I spent five hours just to save the Type-C on the keyboard of netizens

Just a netizen said that its keyboard is broken, and the Type-C interface is not very easy to use, so I think it should be fine to fix it, isn’t it just the keyboard.

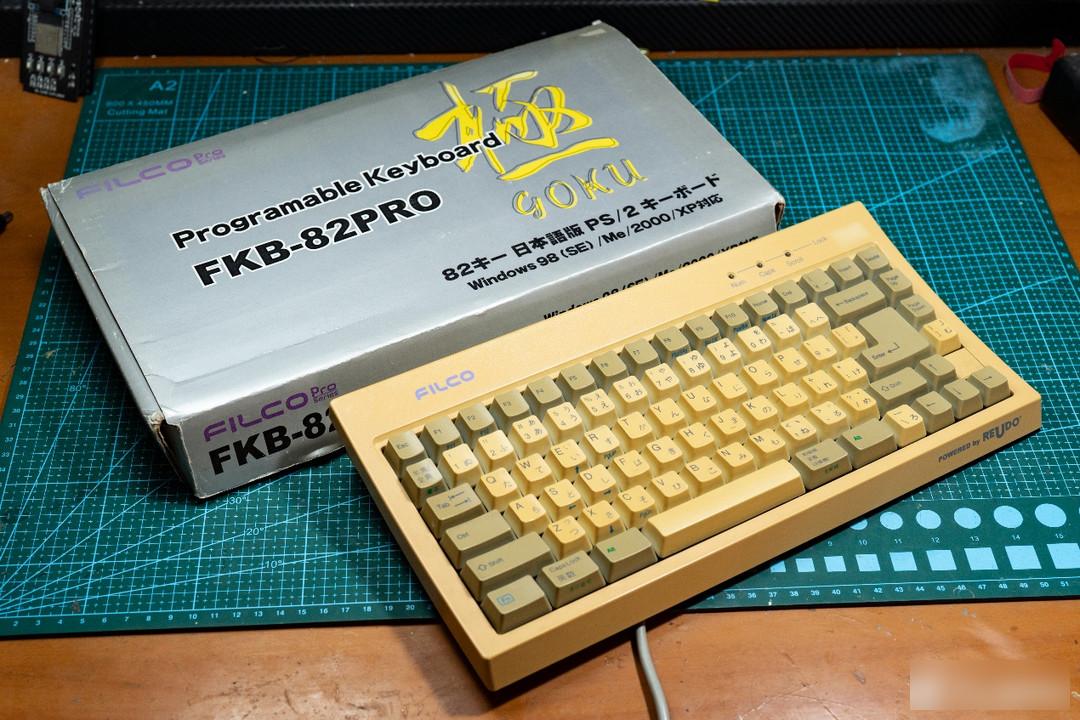

After all, we have repaired quite a few keyboards, for example, an antique Filco was sent over before.

Then when it left my hand, it has become a Type-C interface, which is very practical.

Manual drilling, the other party is very satisfied

Manual drilling, the other party is very satisfied

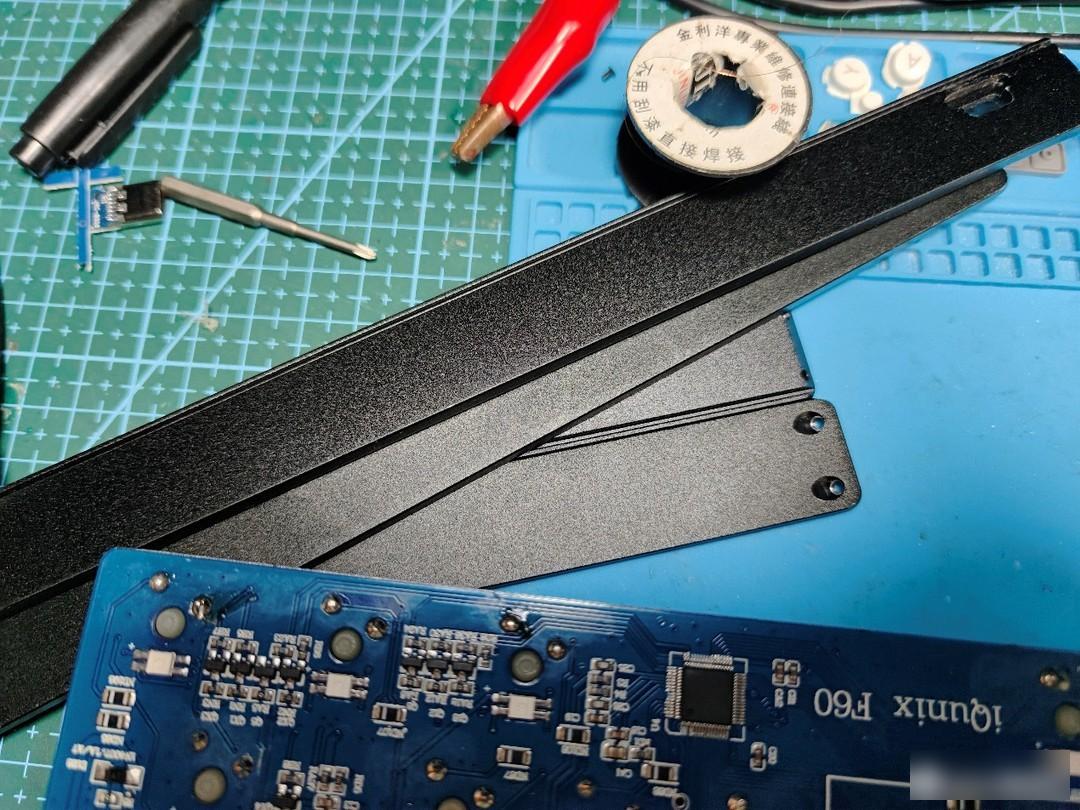

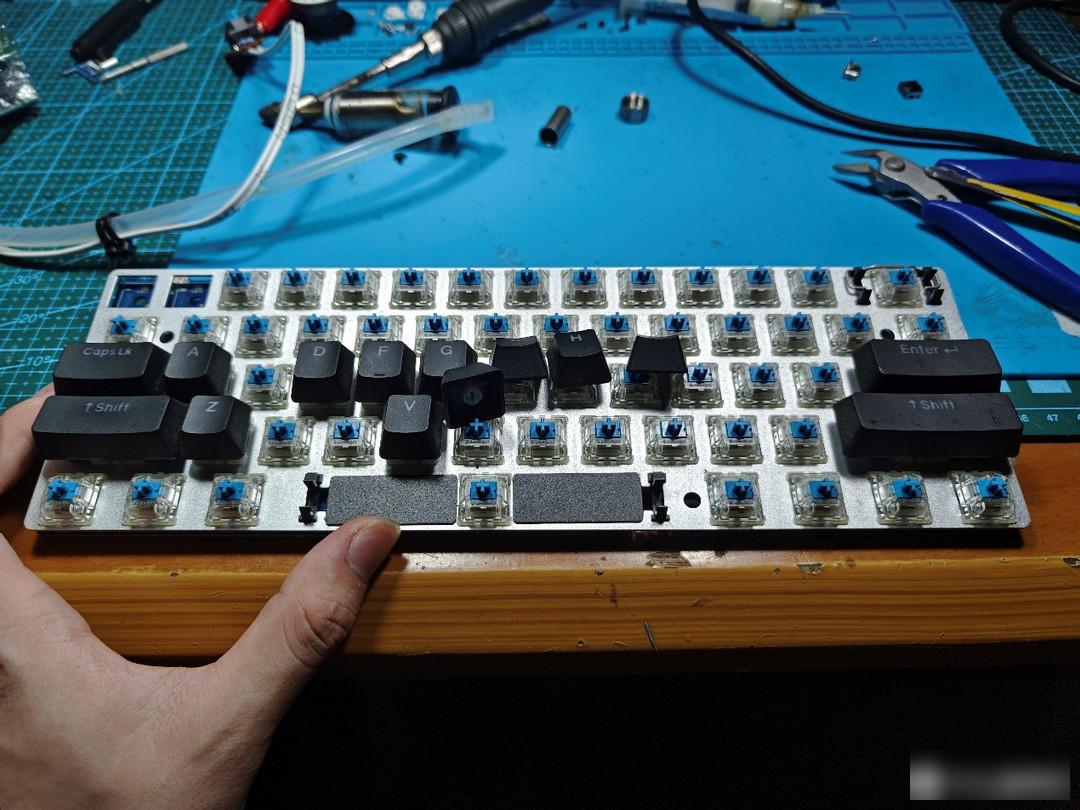

That's very fast. I received such an iQUNIX F60 with a keyboard, and there is a phone number on it, probably because the previous repair failed.

This one is like this, the metal bottom plate and the four-axis are also made of aluminum alloy. This design allows the body to be fully aluminum without a lot of cost.

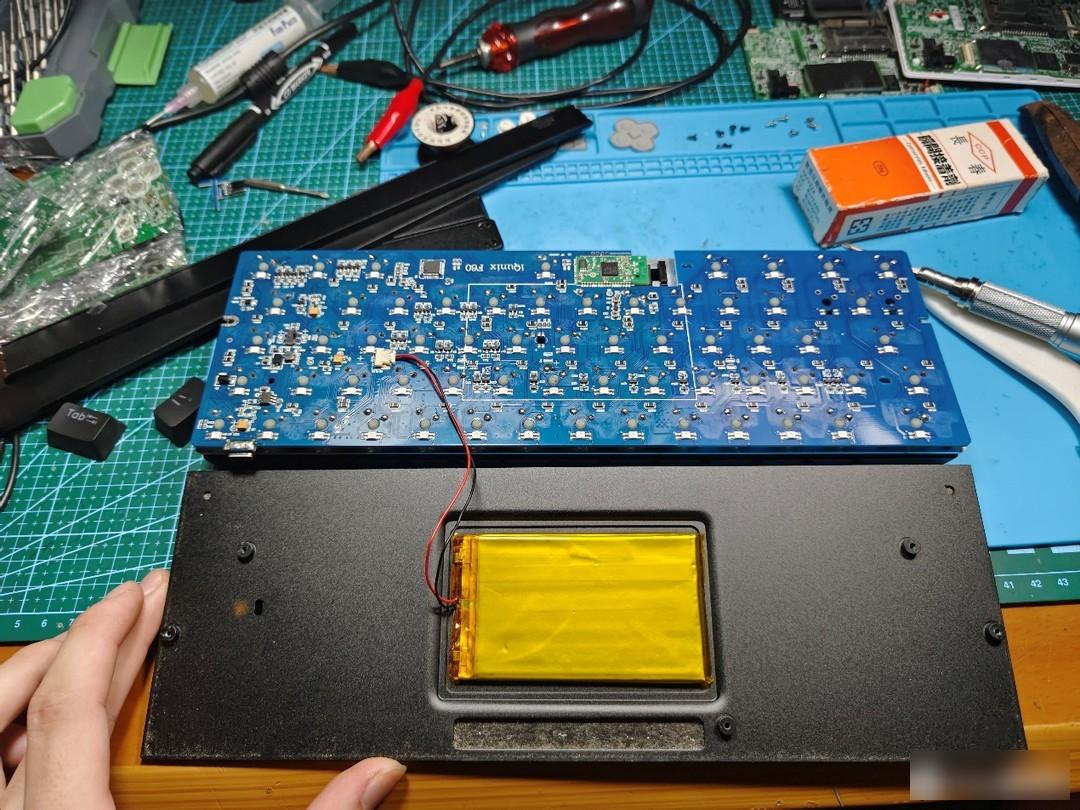

The aluminum alloy cutting at the bottom is done well, and a bulge is specially made to install the battery pack, which is a wonderful cost.

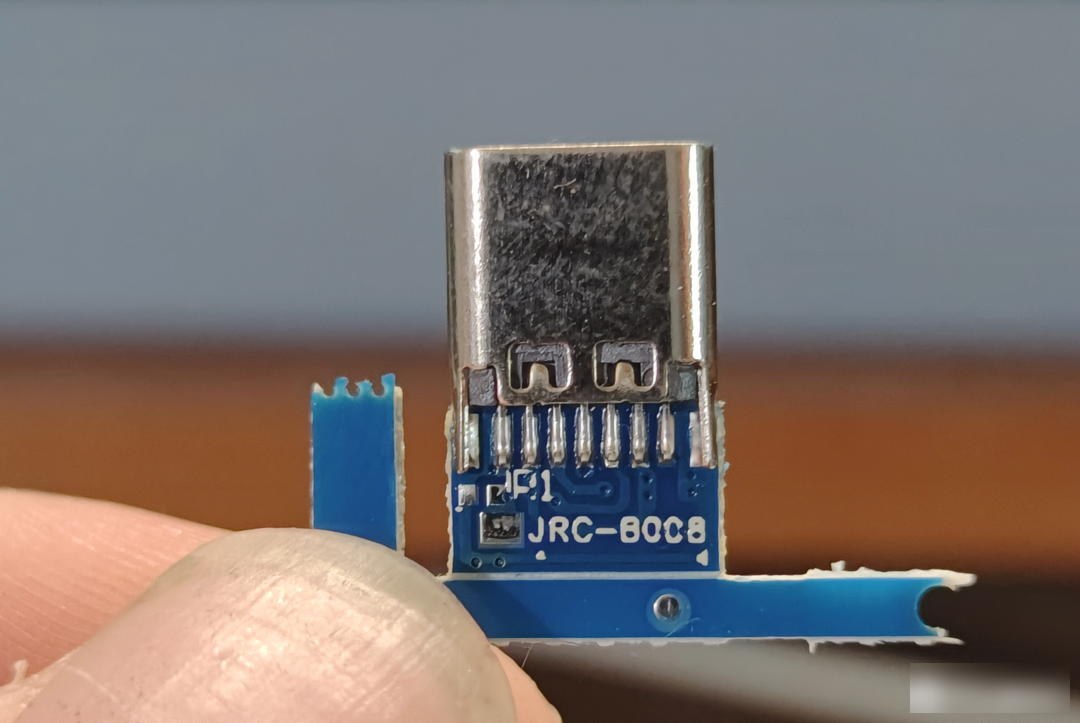

Then what needs to be repaired is the USB interface in the upper left corner. I tried this interface, and the tongue inside is already in a shaking state because it has been unplugged too much. Then there are really no accessories to buy for this thing, I searched the library and couldn't find it.

Here two shafts have been dismantled

Here two shafts have been dismantled

I have compared dozens of models on Taobao, even imported ones, but I still can’t find them.

It's a bit like this one from JAE, but it's shorter. Little knowledge, Nintendo's NS uses this one

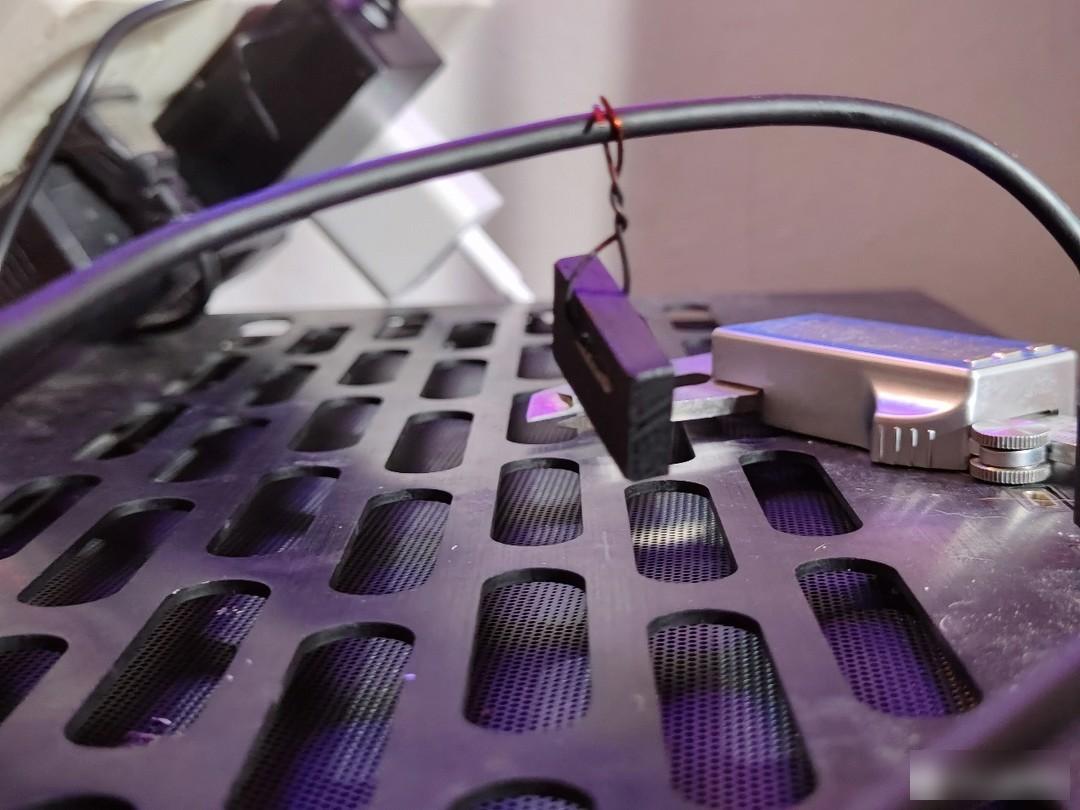

Anyway, the current situation is, no, we can only find another way. Then I thought, how about this, we fly the wire and then lead out the USB interface and transfer it to the Type-C board.

But it is not easy to find the cable for this interface. The Type-C of this model is not on the back but on the front where the key switch is located! In other words, the Type-C interface must be removed only when the shaft is removed. I almost removed all the shafts. I understand how painful it is to remove the shaft.

In the end, at the cost of dismantling 1/4 of the shaft, I barely found the line and welded it.

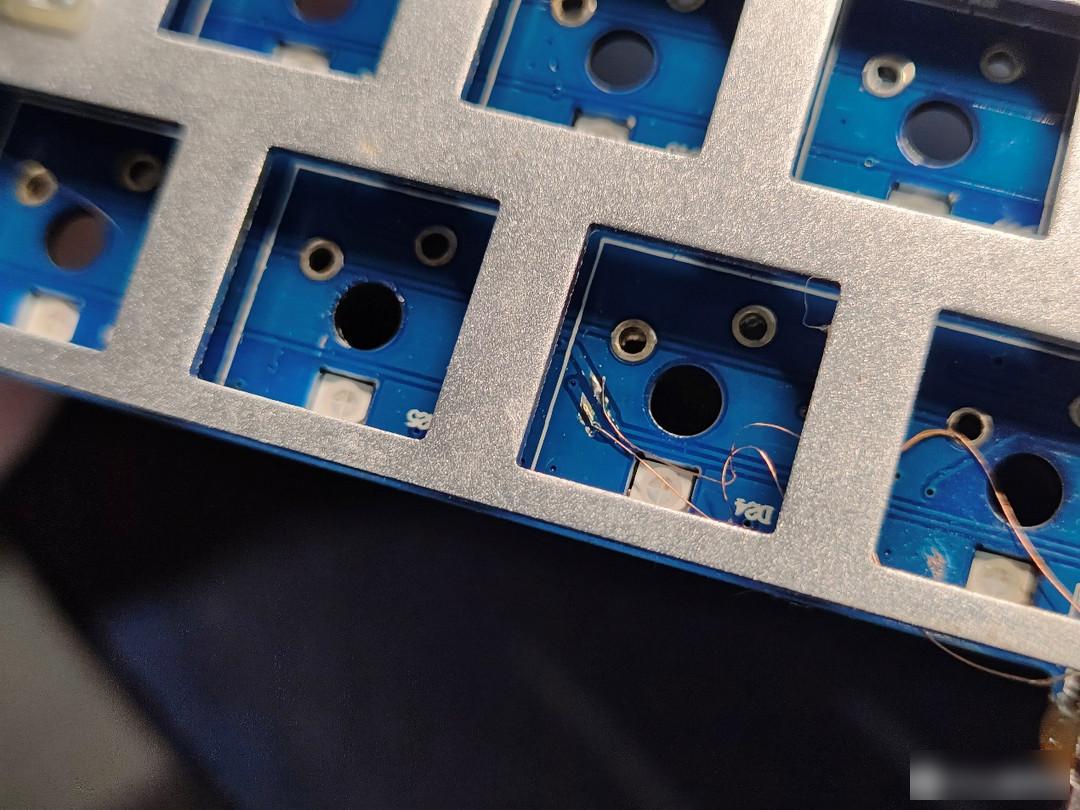

But there are several problems at the same time, except for the design, because this PCB is an early style, its workmanship is not very good, of course, because of the water in the OEM PCB factory, its through-hole part is very fragile, slightly pulled They will all be brought down, see the part in Figure A below.

In the end, I still solved it, but it took extra time to go to the flying line, and then added a button test step.

Now there is a new problem, a large part of the protrusion cannot be inserted into the frame, what should I do, the frame is made of aluminum alloy

The solution is very simple, I have a CNC milling machine, what a coincidence. We can machine the shell, the frame is made of aluminum alloy, the hardness is not high, and it can be done with a tube of cutting fluid

According to a reasonable length, simply open a slot, anyway, let this interface be plugged in first, and I use hot melt adhesive to fix it on the motherboard, and there is no better way

But it's obvious that this doesn't work. The protruding part looks like it's about to break. What should I do?

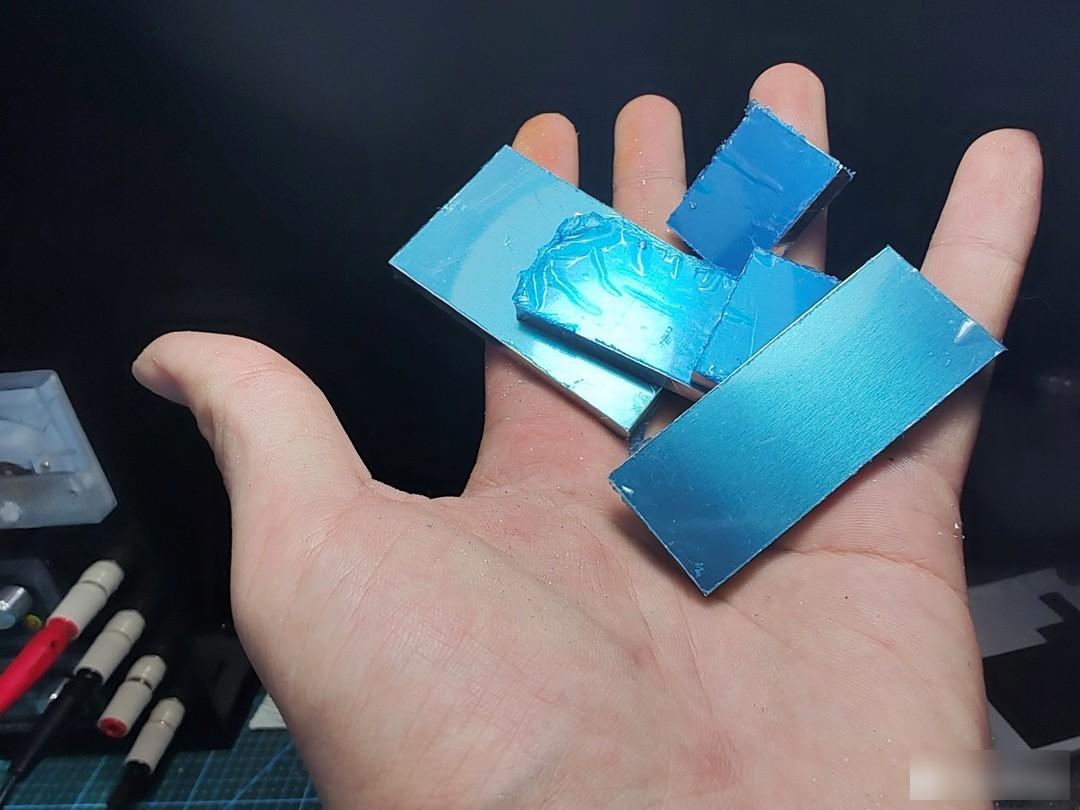

Then I thought that I made a machined part with a hand electric drill a few days ago

At that time, I bought some materials to make this piece, so I can simply use it

Manually adjusted the milling machine, cut a piece, and then milled a slot to pass through the interface.

It's okay after a try, a little error but it can be installed

Spray a coat of matte paint, put it on the case and bake it to dry, and finally spray it twice, and you're done.

The final installed effect is like this

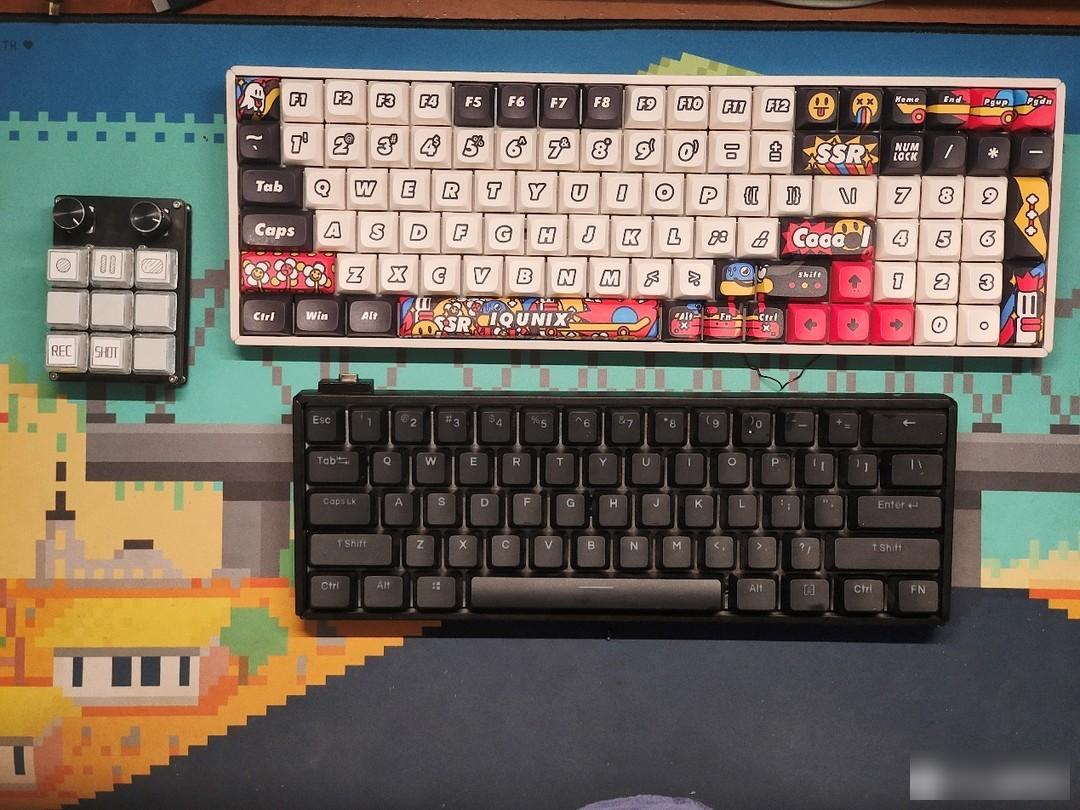

Just recently, I also made an iQUNIX F97. This one is hot-swappable, and it is quite cool. You can see that the 60 is much smaller.

While the paint was drying, I also cleaned the entire keyboard of my commonly used RF 109UG-HiPro. Unfortunately, the steel plate was a little oxidized. I must not be a lazy dog in the future, remember.

Some people may ask what kind of keyboard this is, but I would say that it is an old mass-produced product, but I use it more often than customized ones.

Factory Adress: No.11,FengpingRoad