[Keys are knowledgeable] MILKYWAY——Milkyway R3.5 keycap material evaluation

In fact, this time the tester event made the fans unhappy, and it may be difficult for Mi Kewei himself to get positive feedback from it. I personally suggest that if you want to do this kind of event next time, it is best to make a plan and appropriately increase the threshold for purchase. , such as conditional restrictions such as the previous purchase of Mikovi’s keycaps, or as fan feedback. I believe that Mi Kewei's original intentions are good, but they have been really busy recently, which led to some mistakes in handling affairs.

The sample I received this time is plain white

Let me talk about a few points that I think are more important:

There was obvious melting on the edge of the yellow material on the right. After observing the color depth of the b bond and asking about the sublimation heating temperature of Mikovy, I think this is not a problem during the sublimation process. They also found through subsequent inspections that these Signs of melting are present after the material is released. In this r3.5 version, it can be seen that they have improved, but the signs of edge melting still exist. Regarding how to improve this point, an important point is to start with the raw material formula, and they need to spend money to touch it. Fortunately, the other is a mold problem, so I won’t explain it.

Many friends have asked me about the light transmittance of keycaps. The first point is that "this discussion is not meaningful if it is not based on the ratio of seasoning and pbt." The final effect of keycaps will be affected by many factors. , under limited conditions, good color performance and feel may have to sacrifice shading and other things, but I think that there is no need to compromise to achieve the ultimate good product.

Left r3 yellow material, right r3.5 plain white

The problem is that the keycaps selected this time are plain white, but whether they can guarantee that the keycaps in the future can maintain this light-shielding property is their test.

There are no scratches in my batch of keycaps. From my personal experience, scratches generally appear during transportation and production. If there is no hard object in normal use, scratches are generally not easy to appear. But whether to solve this pain point depends on Mikovi's own follow-up shipments and improvement plans.

In fact, this problem has been reported by people all the time, and it is also a very big pain point.

The plain white space in my hand is relatively curved, but it is still within an acceptable range. Although the after-sales service of Mikovi is very good, the best after-sales service is that there is no need for after-sales. I hope that Mikovi can do this as soon as possible. .

The chrysanthemum of the big key position of the Mi Kewei R3 material is tight, and the R3.5 plain white set is better, in a moderate position (the test uses the cherry shaft as the standard).

Compared with the past products, the glitch problem should be improved a lot.

Mi Kewei's sun pattern should be regarded as commendable, and the hand feel is more delicate and comfortable

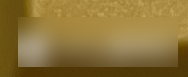

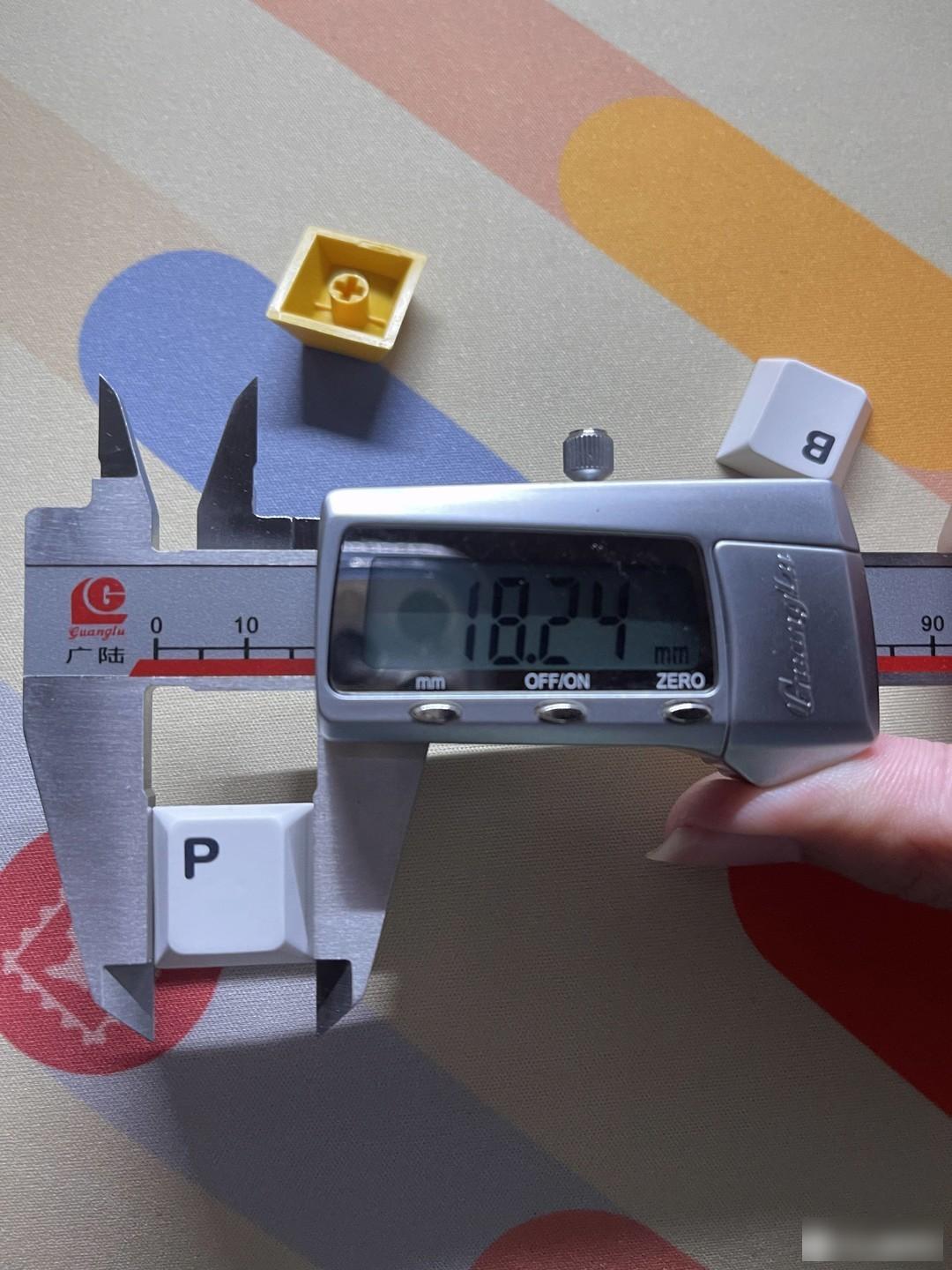

In terms of gap control, Mikovi is still doing very well, and can basically be maintained at around 18.1-18.2.

However, the flatness is not satisfactory, and most of the keycaps are still not straight. I hope it can be improved in the future.

The overall materials have been improved, but there is still room for improvement. I hope that further adjustments and optimizations can be made to the allocation of raw materials and molds in the future.

In fact, my feelings for Mi Kewei are more complicated. From my personal point of view, I hope that more and more manufacturers of domestic original keycaps can make them. At the same time, it is rare for Mi Kewei to provide Manufacturers who help a lot. But as a player, I’m not satisfied with this year’s Mikovi. Delays and various product problems, these costs will eventually be transferred to consumers, and will continue to kill the enthusiasm of players.

All kinds of contradictions have already occurred, and the past can no longer be rewritten. I hope that Mi Kewei can give players a satisfactory answer in the future.

Factory Adress: No.11,FengpingRoad