Mechanical keyboard shaft science popularization part one - the composition and structure of common shafts

Whenever we talk about the current mechanical keyboard and the current switch body, there will always be people who complain about the dazzling current switch body market. Indeed, since the era of black, red, tea and green under the leadership of Cherry has gone forever, a hundred flowers of domestic shafts have flourished, and there are more than a hundred manufacturers and types of shafts. It is easy to be confused without a deep understanding. But in fact, the classification of various shafts has been basically determined as early as the cherry period, and cherry itself has launched various differentiated shafts. Regarding the science popularization of the mechanical keyboard shaft body, we divide it into structure and classification, and let me explain it briefly.

Lifting the mechanical keyboard, lifting the shaft body, no matter in the past or the present, Cherry is still an inescapable existence like Nokia. Cherry is the holder of the early MX axis patent, and is the unshakable leader in the field of mechanical keyboards. This situation lasted until 2014, when the patent expired. The structure of the MX axis is not complicated, or it can be said to be very simple. At that time, the quality of cherry shafts had declined significantly, and China, which was booming in the process of industrialization, took over the baton and became the largest shaft production country today.

To talk about the classification of the shaft body, we must first understand the structure of the shaft body. Mechanical shafts are first divided into contact and non-contact. There are fewer non-contact applications, such as the magnetic axis of Ossair, the optical axis of ROG, and the electrostatic capacitor body... These are mostly products born in special use scenarios, such as for faster triggering of games, for Soft feel, for a longer lifespan... I won't go into details here. Most of the shafts we are talking about now are contact type. The principle is to control the combination of copper sheets through the shaft center, so as to control the on-off of the shaft body, which is similar to the switch, so the shaft body is also called Switch.

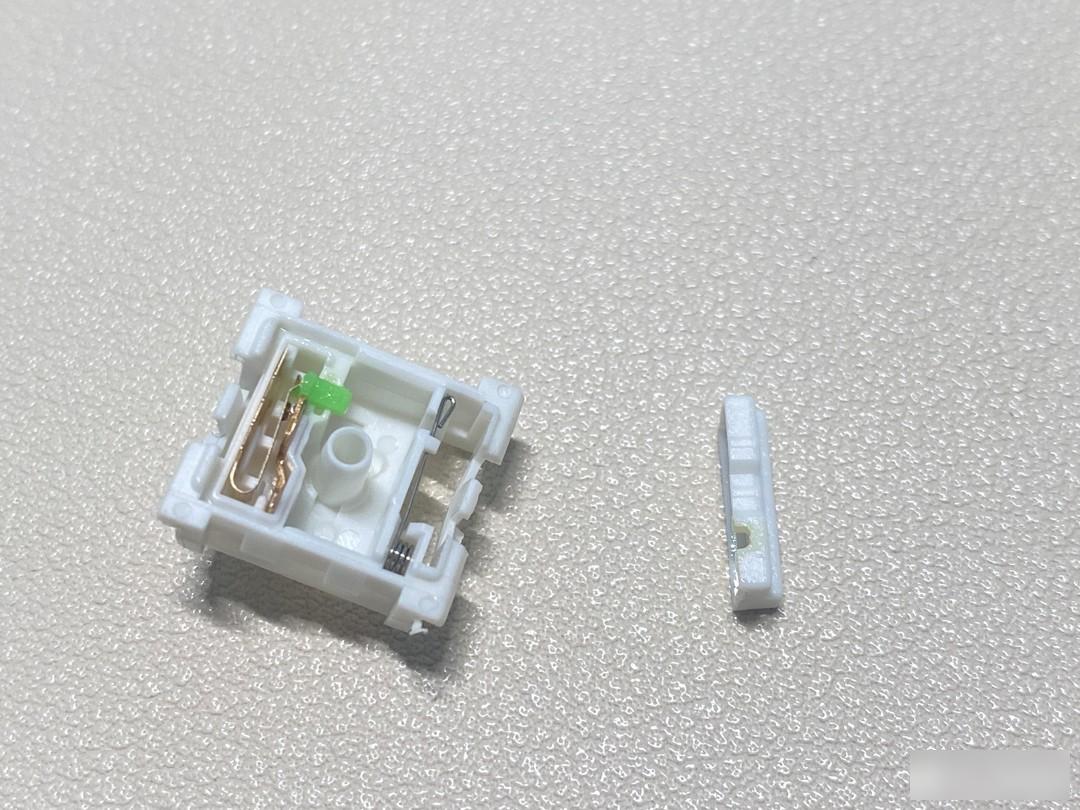

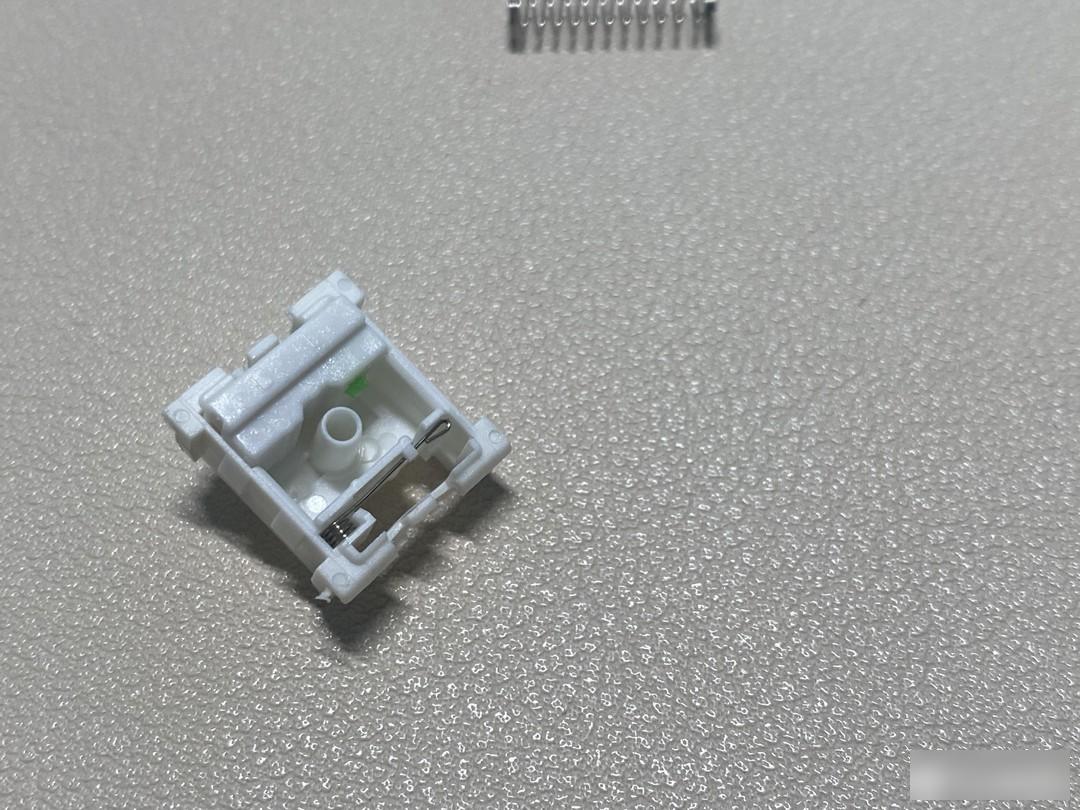

Most of the shafts on the market currently use the cherry MX structure, and there is also a BOX structure, which is the original creation of the domestic manufacturer Kaihua. The shaft body of the MX structure is composed of the upper cover, the bottom case, the shaft center, the spring, the moving piece and the static piece (collectively referred to as the shrapnel), and some shafts also have a light guide column. In addition, there is the special existence of the TTC love axis. Let’s not show it for the time being, and let’s talk about the various parts of the MX axis.

There are not many articles that can be done on the shrapnel. It is ordinary copper. Like TTC, there will be silver plating. It is mainly to prevent poor contact caused by copper oxidation. The difference is not big.

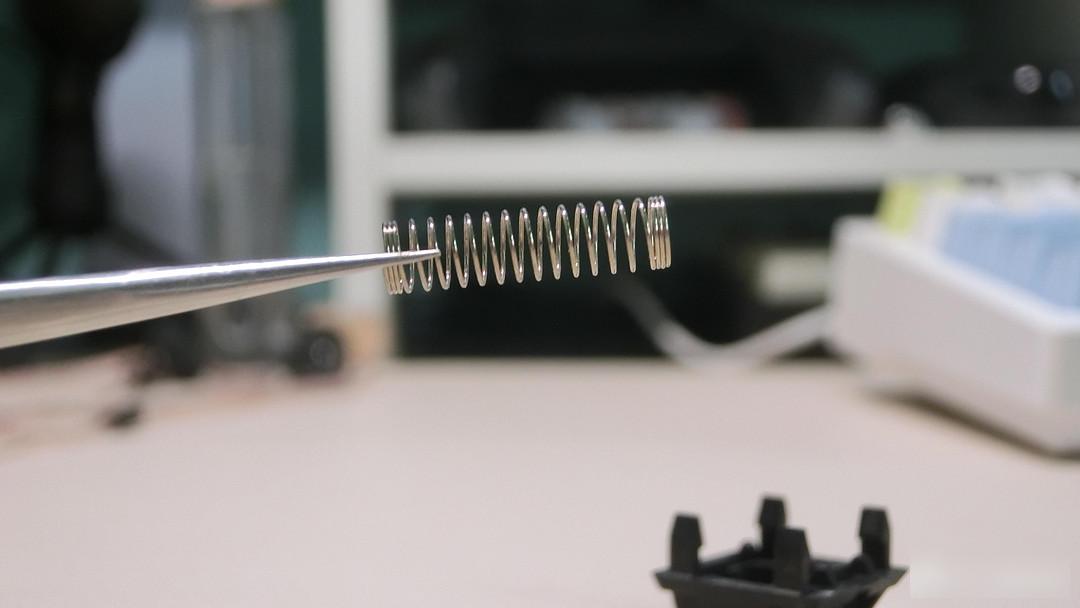

The spring is used to provide the rebound of the button. In theory, the lighter the spring pressure, the lighter the force required to press the button, and the less effort is required, and it is easier to accidentally touch it. vice versa. There are also extended springs and double-section springs. Lengthen the spring, that is, under the same strength, the length of the spring is longer, so the rebound is more powerful. The double-stage spring can provide a certain preload when the shaft body is not pressed down, so it can also ensure the softness of the pressing force when the rebound is strong. Springs are mostly a matter of personal preference.

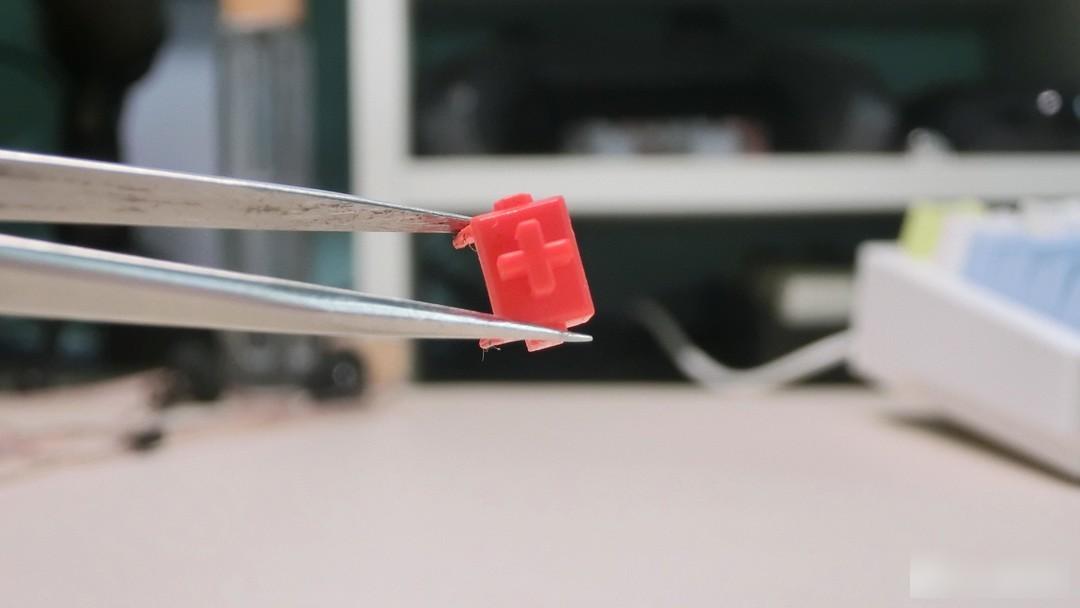

The shaft center is divided into upper and lower parts. The upper part of the MX shaft is a cross, so it is also called the cross shaft, which is used to install the keycap.

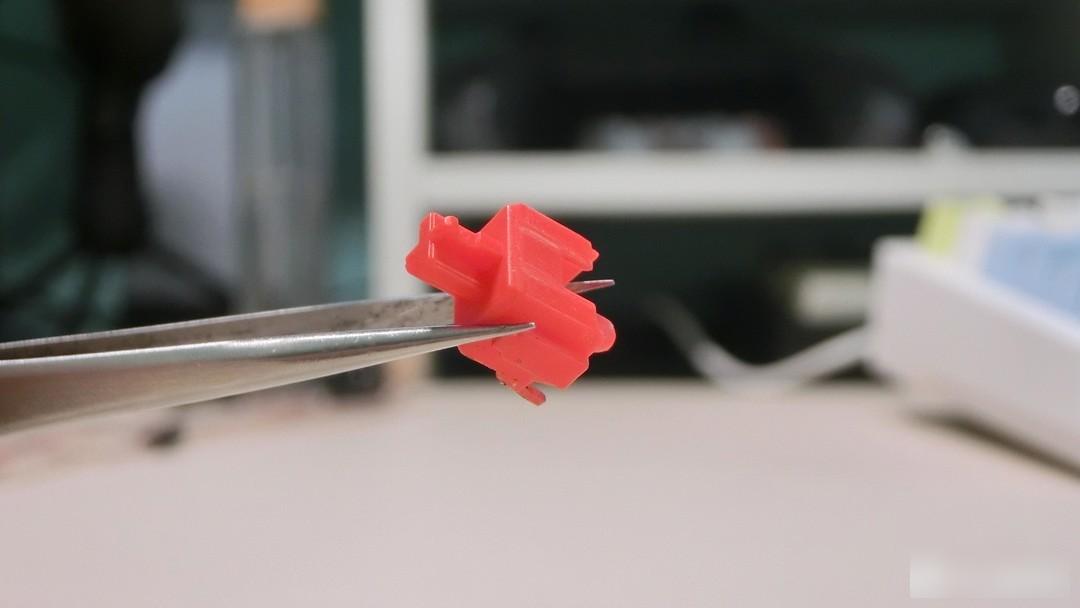

The lower part is responsible for turning the moving piece in the shrapnel to make it contact with the static piece, so as to achieve the purpose of triggering.

In the linear axis, the two parts of the axis are integrated, while in the paragraph axis, the two parts are separated to create a sense of paragraph.

The difference in the axis is mainly in the material and the dustproof wall. In the early days, Cherry switches dominated the world, and domestic switches were mainly used in some low-end markets, such as Internet cafes. The environment of Internet cafes is complex, and dust, soot, etc. entering the shaft body may cause trigger failure, so a dust-proof wall was born, which can block the entry of dust to a certain extent.

The dust-proof wall mainly includes the most widely used open square, the closed square represented by the box axis, and the relatively rare round shape. Now it mainly plays the role of stabilizing the axis, and has little influence.

As for the material, the material of the shaft is generally POM. Because of its self-lubricating properties, it can be used on the shaft to make the shaft press more smoothly.

Then there are the upper and lower covers, which are fixed together by buckles, wrapping the core part of the shaft body, only exposing the upper shaft center and the lower pins.

There are two main shapes of buckles, which can be opened by two kinds of shaft openers.

There are two openings on the bottom shell for the two pins of the shrapnel to pass through. This kind of shaft is called a triangular shaft. And some shafts have two extra plastic columns on the bottom shell to better fix the shaft on the PCB. This is called a pentagonal shaft.

For the general shaft body, the upper cover is made of PC and the lower cover is made of nylon. In addition, the so-called organic polymer materials are actually plastics, and PA66, for example, is actually a kind of nylon. In addition, some linear shafts will use full POM material, that is, the same POM material as the shaft core is used in the upper and lower covers. Because of the self-lubricating properties of the POM material, it is generally believed that the full POM shaft body is smoother than the ordinary shaft body, and the price will be relatively high, and the full POM material shaft body is basically more than one yuan.

Finally, the light guide column. Generally, there will be holes on one side of the shaft body to allow the light from below to pass through. The light guide column is placed here to gather the light, making the light visible to the human eye brighter.

The shaft center moves in the shaft body, which inevitably produces friction, which makes the pressing feel of the shaft body rough. Therefore, it is necessary to apply grease to the spring, shaft and other parts, just like engine oil, and this is to lubricate the shaft. Generally, the shaft will have a certain amount of lubrication when it comes out of the field, which is factory lubrication. Excellent factory lubrication can improve the service life of the shaft, reduce the noise generated by the movement of springs and shrapnel, and also make the pressing feel of the shaft become better. smooth.

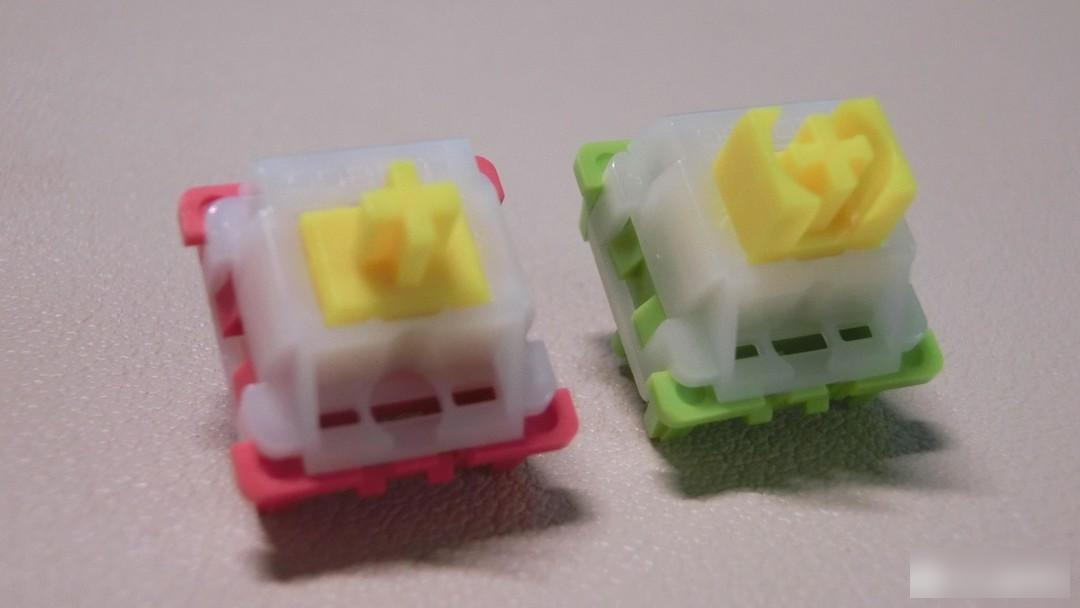

After talking about the conventional MX axis, I have to mention the unique BOX structure of Yusan Zhongkaihua. The axis body of the BOX structure is named after it looks like a delicate small box, and its appearance, compatibility and triggering principle are the same as those of the MX axis body.

The main difference lies in the arrangement of the internal components. The protrusion on the BOX axis moves a "small green dot", and the green dot then moves the moving piece to make it contact with the shrapnel.

In addition, the biggest difference in the BOX structure is the principle of sound production. Another bump on the axis moves the torsion spring to make it produce sound. This also creates a unique paragraph axis in the BOX family.

The structure of the shaft body is roughly like this, if it is too long, you don’t like to read it. In the second half, let me talk about the classification of the current complicated axes.

Factory Adress: No.11,FengpingRoad