Pitfalls of Mechanical Keyboards Part 5: My Union Mechanical Keyboard - The Finale

This is a series of articles, recording the process of designing and assembling the mechanical keyboard by myself, reviewing the previous situation:

Hello everyone, I am Wuchen . I'm here to hand in the paper

If nothing else, this may be the first in the world, combining the achievements of Filco and Logitech Union, while sitting on three-mode , small arrangement, Union , low power consumption, Full key programmable All-in-one mechanical keyboard

please allow me to show off

please allow me to show off

please allow me to show off

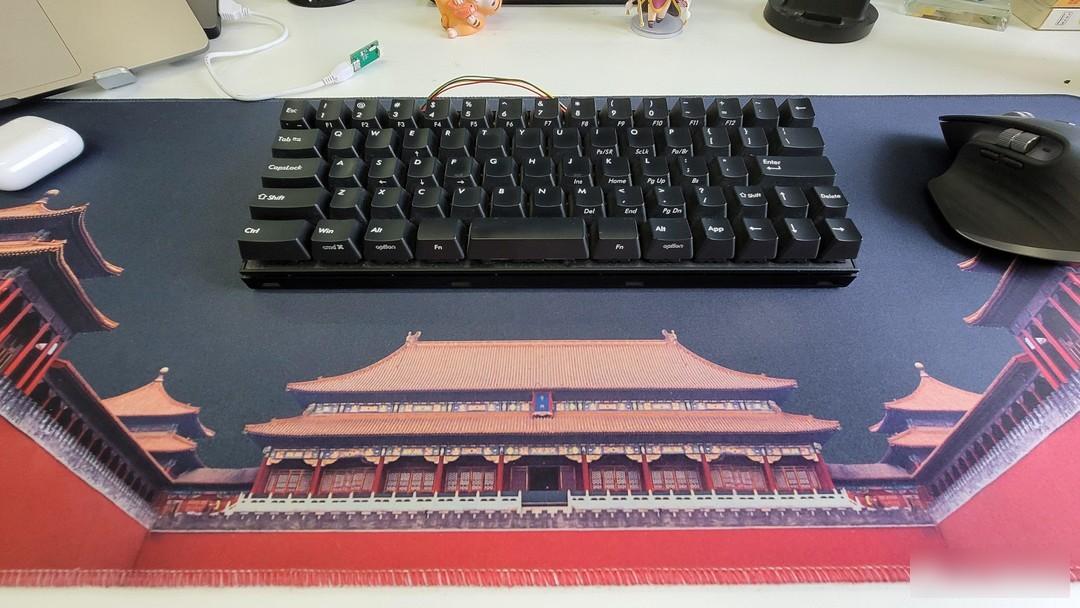

First picture:

Um? Isn't this just an ordinary minila air keyboard?

Don't worry, we can't just look at the appearance. As the saying goes, good-looking skins are the same, and interesting souls are one in a thousand. Under the seemingly ordinary appearance, there is a distinctive "core":

now that's it

now that's it

now that's it

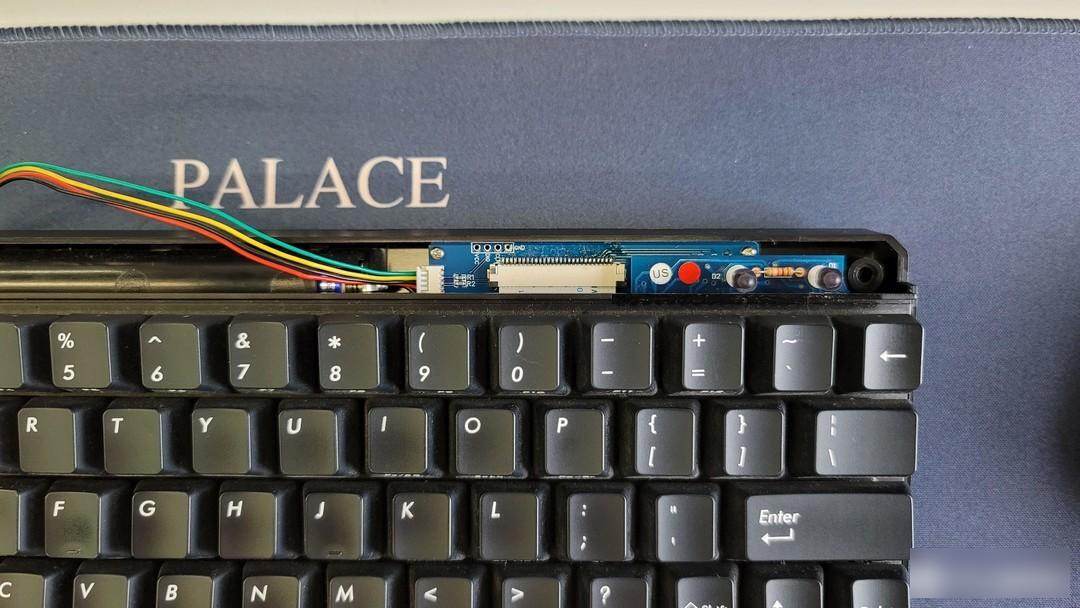

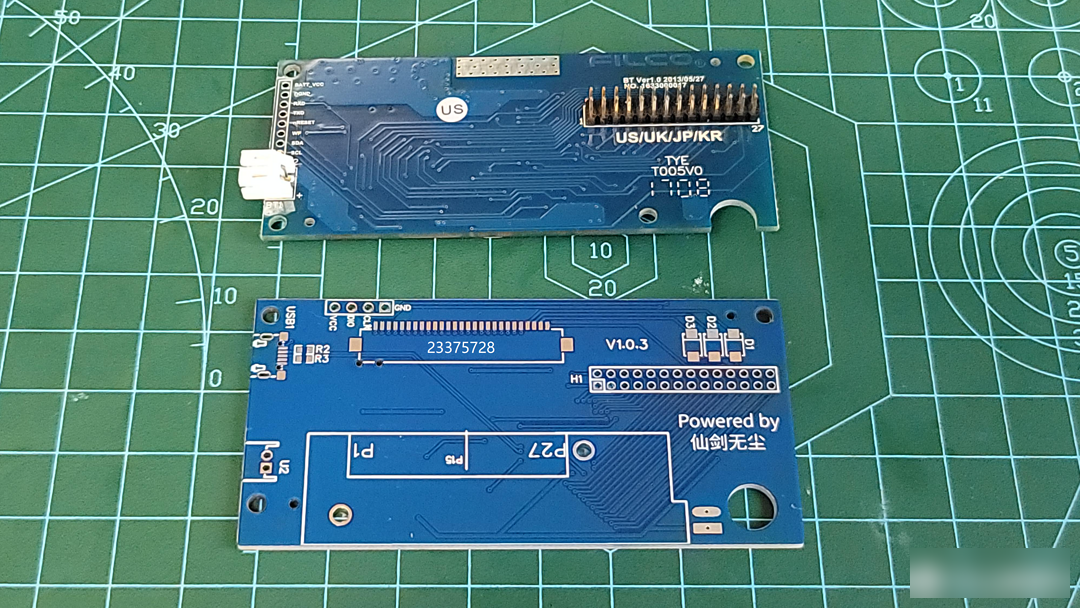

Here's a close-up, the top is the original master control of minila, and the bottom is the super enhanced version designed by me, which has been iterated to version V1.0.5

Here's a close-up, the top is the original master control of minila, and the bottom is the super enhanced version designed by me, which has been iterated to version V1.0.5

Here's a close-up, the top is the original master control of minila, and the bottom is the super enhanced version designed by me, which has been iterated to version V1.0.5

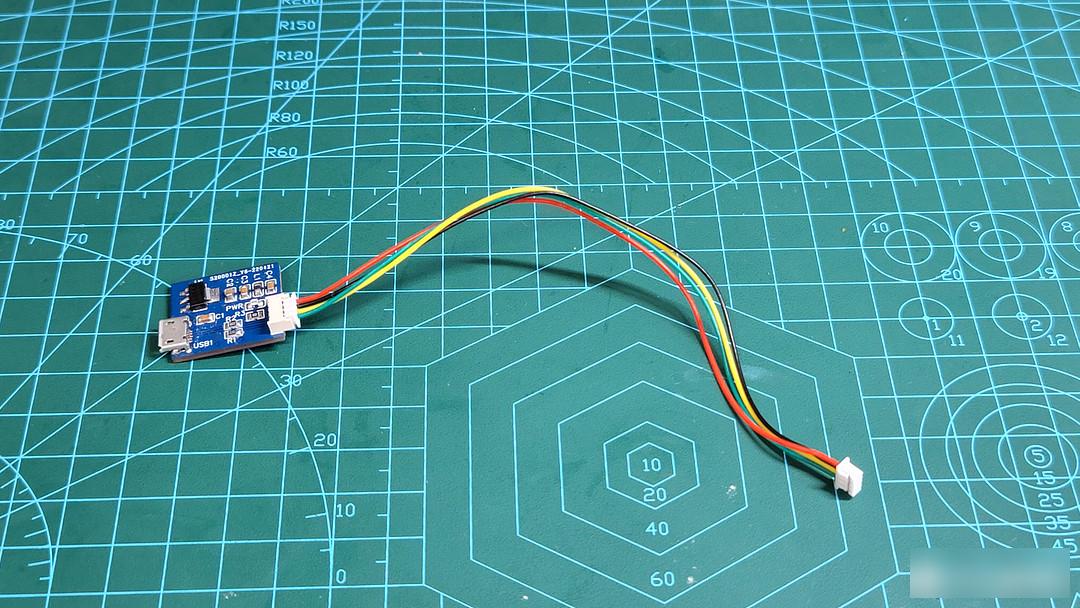

Considering the adaptation of other shells, a small board is made separately for the USB terminal

Considering the adaptation of other shells, a small board is made separately for the USB terminal

Considering the adaptation of other shells, a small board is made separately for the USB terminal

Tsk tsk, the more you look at it, the more beautiful it is, the dreamy combination of the three giants in the global keyboard industry, everyone, are you sure you don’t want to come to a set??

Detailed features:

Three-mode, wired, bluetooth, and 2.4g Union . Among them, the wired and 2.4g modes support the use of BIOS

Support custom arrangement, Full key programmable in all three modes

Wireless based on Logitech K375S, Support full Unified features (Bluetooth, 2.4g, low latency, stable, power saving)

Supports Logitech Flow, Seamlessly and automatically switch between different devices (It needs to be eaten with a mouse that supports Logitech Flow, I use Logitech Master 3)

Fast wake-up from hibernation , the first key can respond (Minila original Bluetooth, it takes 2-3 seconds to wake up, and the key does not respond during the wake-up process, the experience is very bad)

The K375S native Fn key is mapped to the second-level key value, which can switch up to 3 devices through shortcut keys (no need to flip the keyboard operation)

Filco minila air original matrix PCB board, positioning board, shaft, cap, Retains the delicate feel of the big F, tuned by a big factory, authentic

Perfect support for Filco minila air bluetooth wireless version case (battery compartment, LED indicator light, power switch, reset button, 6-position DIP switch)

Support wired version minila to wireless three-mode. In theory, except for minila, any small configuration matrix can be supported (welcome small partners in need to come and harass, maybe you can drive a wave car)

Although it was completed faster than expected, the process was not without twists and turns

After getting the first board back from Jiali Chuang, you need to solder the components on it first. Speaking of welding plates, that was also the first time a big girl got on a sedan chair. If a worker wants to do a good job, he must first sharpen his tools, and he must not be sloppy when it comes to tools, and he opened the buy, buy, buy mode:

Do you all know these?

Do you all know these?

Do you all know these?

Too little table space, peg board YYDS

Too little table space, peg board YYDS

Too little table space, peg board YYDS

Before actually doing it, I specially reviewed a lot of circuit board soldering tutorials. When I watched the video, I thought, well, it is quite simple, as long as you have hands. To the actual operation, I suspect that I may have a prosthetic hand

There is nothing difficult in the world. After continuous practice, it turns out that the soldering iron does not need to be hot. It turns out that the solder has specifications. It turns out that the heat gun will blow the SMD components away. ...don't ask me how I know this...

After finally soldering out the first main control board, I couldn’t wait to power on the test. If there is no accident, there is still an accident: the computer cannot recognize

Comfort yourself, the probability of success in the first board is extremely low, unless you are very talented. Let me wait for mortals to calm down and analyze what went wrong.

When I was thinking hard and couldn't find a clue, I wondered if it was a problem with the data cable. I immediately changed the data cable and plugged it into the computer. "咚咚", the computer successfully recognized

Haha, it's really a problem with the data cable. I didn't expect to design and solder the circuit board for the first time in my life.

After being excited for a long time, I still calm down. The first step of the Long March is a long way to go. The real difficulty is yet to come.

Although the position of each positioning hole, screw hole, and component is checked with a caliper, there is still an error. One of the positioning holes cannot be put in. Of course, obsessive-compulsive disorder cannot bear it. Re-measure and then build the board. It takes more than half a week to play a board, and most of the first month is spent waiting for the board. However, after playing a few versions, I found that my proficiency in schematic diagrams and pcb layout is getting higher and higher. It took more than half a month to make a version before, but now it can be done in less than a day. After the third edition, the circuit board finally fits perfectly with the shell, and the wiring and layout are also optimized

After the circuit board is OK, continue to work on the software, upgrade the system to the latest, then transplant the previous test code, correct the non-standard parts, and write the formal logic. The logic is not complicated, and with my software background, it is relatively smooth

Because the minila original matrix circuit board needs to be reused, the next step is to measure the original minila matrix first, and then make a matrix table according to the key value. Manual labor, no technical content, and it is completed quickly. Enter the matrix table into the code, burn it, insert the USB cable, and successfully recognize the keyboard, the key value is normal, and the shortcut key is normal

So far, it took three years to finally transform the Bluetooth version of the keyboard into a wired version

The reverse operation is the most deadly

The reverse operation is the most deadly

The reverse operation is the most deadly

Of course it's not over yet, we have to add a heart of Youlian to it. Everything seems to be going very smoothly, and I feel that the task can be completed ahead of schedule in May, and I am ecstatic. If there is no accident, there will be another accident

Sure enough, in the process of driving the optimization, it was first found that the main control frequency was insufficient, which caused the keys to be triggered and connected by mistake; then it was found that the key trigger delay was abnormally high (up to 300ms), and the k375s could not be woken up normally after sleep

These two problems can be said to be the biggest stumbling blocks, because they are the limitations of the hardware itself. If you are not sure, you can change the hardware chip solution, overthrow all the design and start over, or the whole project will fail?

I have been groping in the dark for 2 weeks, and I have consulted the bosses in various forums and groups, and various measurements of Union matrix scan mode (after research, I found that Union is not a standard matrix scan timing, and it has been specially optimized for power saving, YYDS? ?, but this also brings more complexity to driving it, and I will have a chance to talk about it in detail later), I tried all the methods I can think of, but there is still no progress. Although I didn't want to admit it, I felt that this was the end of it, and I wanted to give up several times. However, one morning, when my eyes were sleepy, a wonderful idea suddenly popped up in my mind. Carp stood up and got out of bed, with his fingertips flying and jumping on the keyboard, compiling, burning, running, waiting quietly, one minute, five minutes , ten minutes...an hour has passed, the test passes, everything works fine. The feeling at this moment is so wonderful that I can't describe it

As of now, using this keyboard to write manuscripts, Hole dug 3 years ago It finally ended perfectly, dreamlike and fantastic. There are countless big and small problems solved in the process, hundreds of TODOs are full, and it is difficult, so I will not express it for the time being

Some friends may want to know how much it cost in total, so let’s list it roughly:

Second-hand minila keyboard * 2, about 800 yuan

Second-hand left shift 64 keyboard, about 200 yuan

Logitech K375S keyboard * 2, about 150 yuan

2-in-1 soldering station, about 280 yuan

Consumables such as solder paste, solder wire, tin absorber, tin absorber, etc., about 300 yuan

Components, about 200 yuan

Development board, about 200 yuan

Dupont wire and other materials, about 30 yuan

time, unknown

How much the overall cost is, you can calculate it yourself, anyway, I don’t want to calculate it (severely overspending...

)

)

After spending so much, what have you gained:

just fine keyboard

Several tools

Basic circuit board design and fabrication skills

Grandpa of XXX judge (yes, you in front of the screen)

Good habit of getting up at 6 o'clock

Whether the input and output are worthwhile, everyone must have their own judgment. For me, after overcoming the difficulties that I once thought were impossible, the whole city was still asleep in the early morning. When the code I wrote by myself was successfully run on the main control that I soldered by myself, the indicator lights flashed rhythmically. At that moment, what you are holding in your hand is no longer a cold circuit board, it seems to have its own life, quietly and firmly declaring your existence to the world. This kind of experience can only be understood by those who have experienced it.

In the last article, we talked about the company Jiali Chuang, so here are a few more words.

When deciding to design and manufacture hardware circuits by myself, the most widely used and powerful Altium Designer (known as AD) was the first to learn. The software operation is not bad, but it’s 2202. At the beginning, I had to draw the package by myself. Duplicate work is a waste of life, which makes people feel that AD is quite old. So he turned to the independent and free Easy EDA in China. Because it is based on the front-end architecture of the page, it has the advantage of cross-platform, but the performance is slightly affected, and the operation is not as smooth as AD. But I can't resist the fragrance of the official packaging library and user library that I have just raised my hand. It is so friendly to novices like me. It is no exaggeration to say that without the powerful packaging library of EasyEDA, my hardware design path may be discouraged at the first step

In addition to the packaging library, Easytronics has also opened up the entire process from design to board making, and the whole process is self-service. You must know that before Easytronic, you need to go back and forth with the factory to make a circuit board. I don't necessarily care about you yet. Jia Lichuang has greatly reduced the hands-on cost of students and electronics enthusiasts. The one-stop service of Easy eda, open source platform, Easy Mall, 3D printing, and training camp is simply YYDS. Because of his existence, the knowledge and talents of many people can bloom and bear fruit at a very low cost (any small obstacle may cause a creative idea to die). Therefore, the greatness of Jiali Chuang lies not only in how much money it saves everyone for free, but also in the huge social value he brings through model innovation. I have to give it a thumbs up.

Show off some of my achievements in Jiali Chuang in the past three months:

Why did you mess up two shortcuts? Because Easy 2 times free use up - -!

Why did you mess up two shortcuts? Because Easy 2 times free use up - -!

Why did you mess up two shortcuts? Because Easy 2 times free use up - -!

You can't just pluck the wool, you have to feed the sheep and graze. No, I have also ordered a lot of components and tools in the Lichuang Mall. Although not much contribution, but wishes are good : I hope Jiali Chuang can grow bigger and better, and continue to bring more benefits to everyone~

I would like to make a small suggestion here, hoping to adjust the free boarding strategy, reduce the number of boards each time to 3, and increase the number of free boards per month to 4 times (or only limit the total number of boards per month, unlimited boards frequency). For students and individual enthusiasts, generally 5 boards cannot be used up (3 boards are enough considering the possibility of welding damage), and many boards are wasted; for big bosses who want to mass-produce, 5 boards and 3 boards are no different . In this way, without affecting the total number of boards, it not only avoids the waste of boards, but at the same time, everyone can have more opportunities to play boards (change boards), wouldn't it be fun.

Friends who agree should like it

Now that chip prices are rising, I am also paying attention to domestic alternatives. One of the players is ESP32, which has built-in WiFi and Bluetooth. During the process, I found a place where I can get a development board for 1 yuan, and I have successfully obtained one. Friends who need it can click the link below (you can get extra points), and sign in in their software to exchange for a development board:

Click me to roll ESP32 development board

So far, the journey of "making" mechanical keyboards has come to an end

Bar?

After spending so many beautiful mornings and weekends, I finally learned the design and production of hardware circuits from scratch. It's over, and I still have more to say, so... let me know what else I can do.

Thank you for your continuous support, if you think our keyboard is okay, Welcome to like, collect and follow , feel free to leave a message if you have any questions

I am Wuchen, see you next time

Factory Adress: No.11,FengpingRoad