Talking about Software and Hardware Part 150: It is the first time to play customization, I suggest paying attention to these problems

suite

The arrangement of the keyboard has long been derived from the original 104/108 key arrangement, and various arrangements such as 87/84, 61/68/71, 40, 98, and 75 have been derived. Some seemingly strange arrangements are actually made by ordinary users according to their own needs, and then quantitative production is carried out. The really popular customized kits are the three configurations of 68, 87 and 104/108. For example, the Black Canyon Soda68 is the classic 68% arrangement, and there are also 61% and 71% arrangements of the same origin, that is, a few more buttons or knobs.

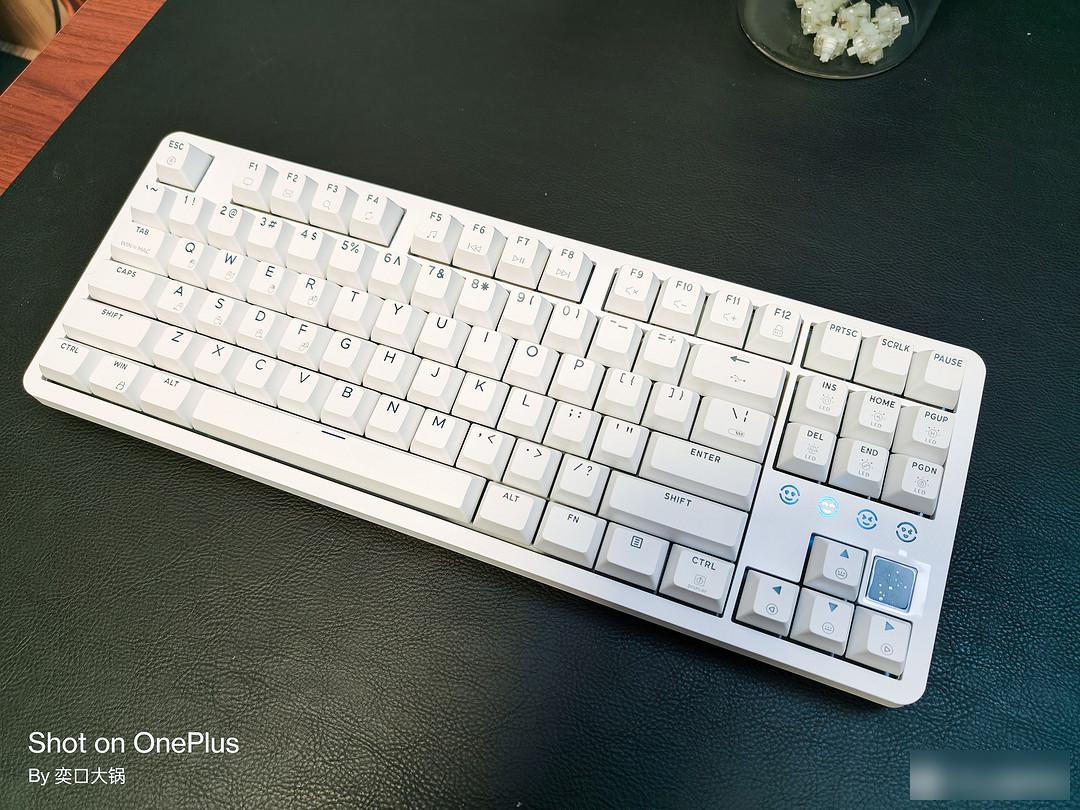

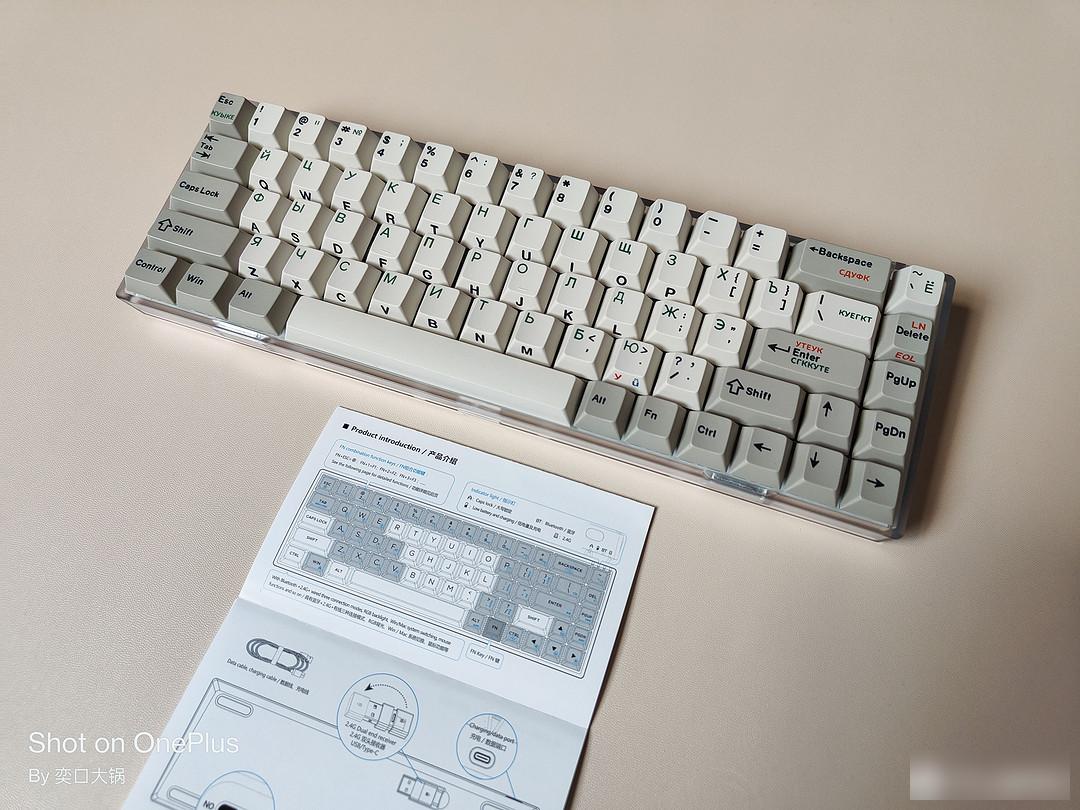

The Y3 is a standard 87-arranged keyboard, and the switch body supports hot swapping, which can also be regarded as a kit to a certain extent. After all, the switch body and keycap kits are bundled, and you have to install them one by one after you get it. The 87 has the same source as the 84/86 arrangement, which also increase or decrease a few keys and multiple knobs. The specific choice of which one to arrange depends on your own needs and budget.

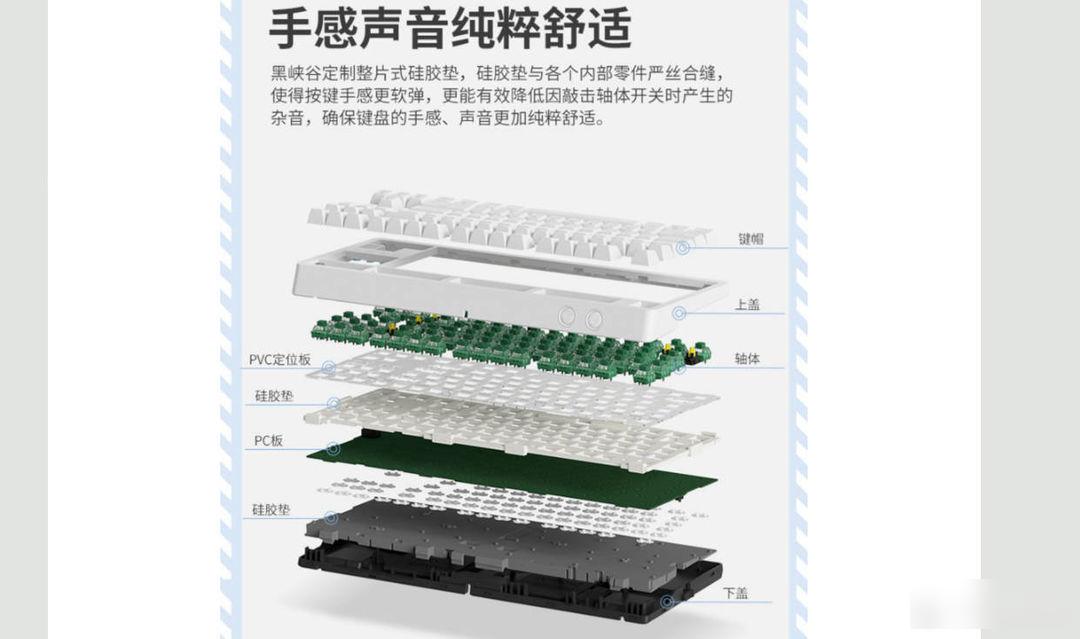

The simplest keyboard structure is the sky-covering structure with an inner liner sandwiched between the upper and lower covers, and the entire keyboard rings when you type it. Later, a more complex structure and connection method evolved. Take Black Canyon as an example: a layer of silicone sandwich pad is added between the positioning board and the PCB board, and a layer of silicone bottom is also added between the lower cover, battery and PCB board. Pad, to reduce the vibration and noise of the keyboard as a whole, but also to ensure the rebound feel.

In the past, many customized cases required self-welding, because there were tools and technical thresholds for welding, and there were many individuals who undertook generation assembly on various platforms. The relative cost of hot-swapping has dropped in the past two years. For kits of the same level, the price difference between soldering and hot-swapping is already the same as the price of a set of soldering tools. If you want to try more axes, there is no The reason is not to choose a kit that supports hot swapping.

The length of the large keys on the keyboard is usually 2-3 shaft widths, so there must be an auxiliary mechanical structure to ensure the normal use of these keys. Soda68 uses the satellite shaft structure, which is the most mainstream large key structure now, and the balance bar is basically no longer seen.

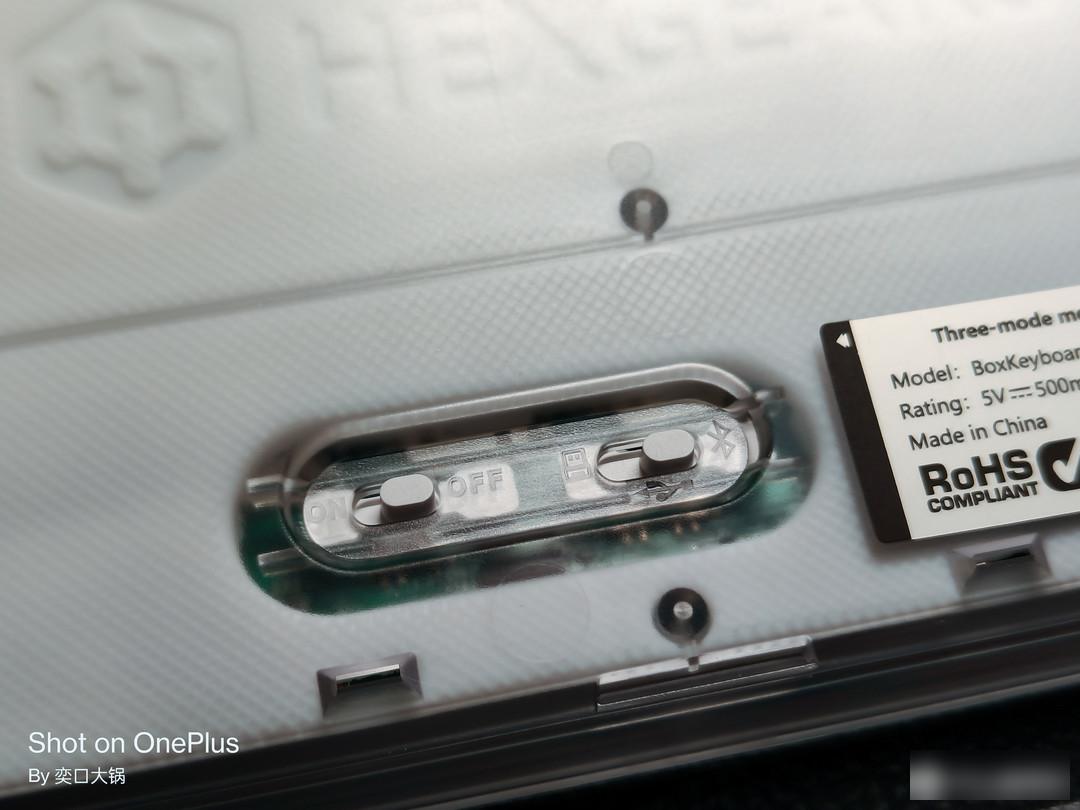

Since the cost of customized self-assembly is higher than that of finished keyboards of the same specification, wired keyboards are still in a frantic price war, and the main shipments of existing kits are still wireless models. The wireless connection of the keyboard is basically realized through Bluetooth or 2.4GHz adapter. Wireless dual-mode generally refers to supporting wired and Bluetooth connections, and wireless three-mode supports wired, Bluetooth and 2.4GHz connections. The switching of the three modes and the switching of the keyboard are mostly controlled by physical switches. Most of the keyboards that support Bluetooth connection can be paired with 3 devices. The corresponding device can be selected through the Fn function key and the corresponding button. The lights of these keys will also be used to display the Bluetooth connection status. Taking Soda68 as an example, these 68 keyboards are conventionally connected to Bluetooth devices through Fn+Q/W/E switching.

Shaft

There should be hundreds of shafts now, and it is impossible for ordinary people to try all of them. But as mentioned above, the shaft body is divided into two categories: paragraph and linear, and there are different pressure grams and strokes on these two basis. Therefore, you can estimate the axis body that you are familiar with based on the data of the axis body. If you really can't estimate it, you can also buy a shaft tester to try, and then just take out the shaft tester after you are selected.

This time, we chose the Runyu shaft from Cherry Five-leg Factory. The jade shaft is based on the white shaft by replacing the spring, grease, and using updated processes and standards. The trigger pressure is 44cN, the stage pressure is 55cN; the trigger stroke is 2.0mm, and the total stroke is 4.0mm. It can be understood as a combination version of white shaft and brown shaft, providing a total of 8 styles of three-legged/five-legged, RGB/non-RGB and factory-run/non-factory-run.

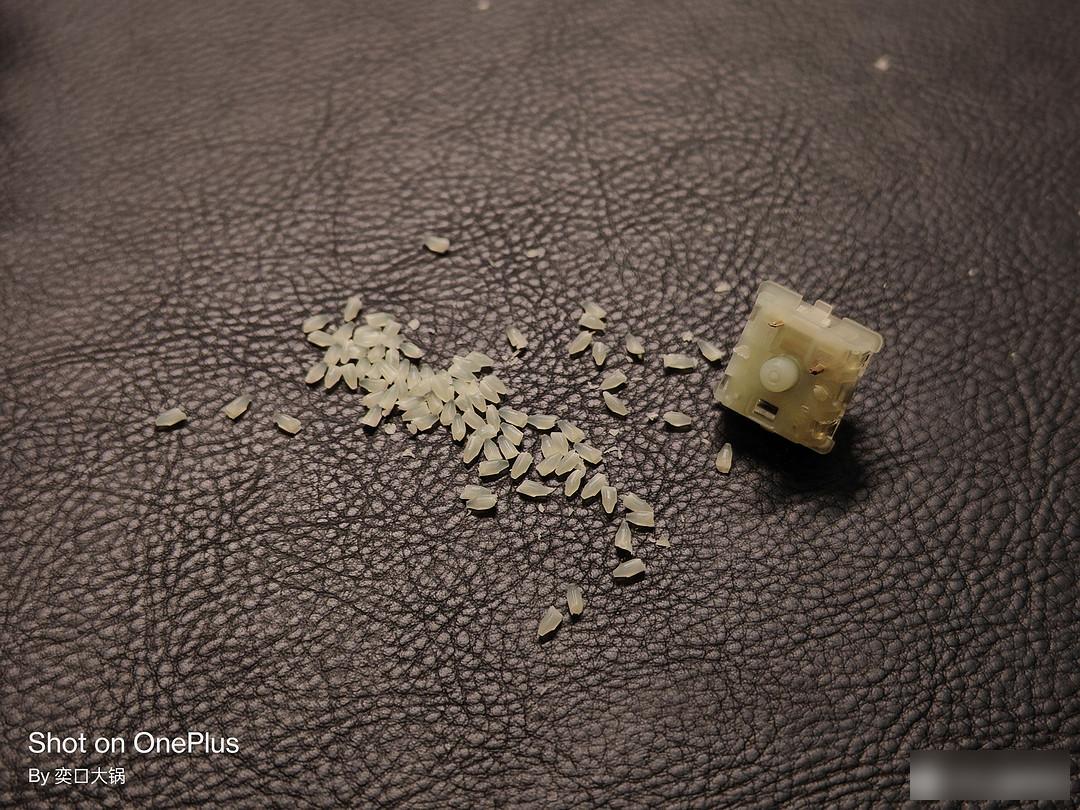

In the circle of customization, there is another key point: run shaft. In the author's opinion, the shaft body is most affected by the innate craftsmanship level, so it is like rubbish shaft moistening can save the hand feeling, and some shafts with better craftsmanship have to find the so-called generation group to moisten the shaft, which is pure waste. . To put it bluntly, running the shaft can improve the friction between the shaft core and the base, and improve the smoothness most intuitively. Disassemble the shafts one by one to do the so-called lubricating shafts. If you insist on lubricating the springs, you can avoid the sound of the springs.

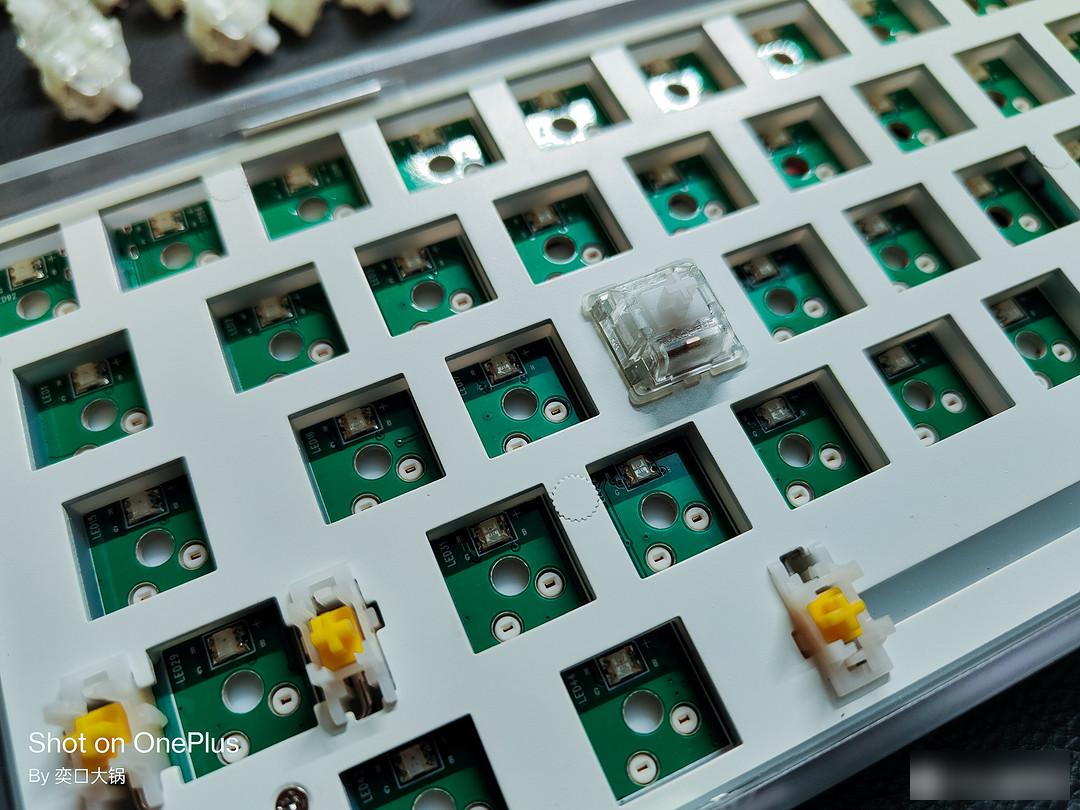

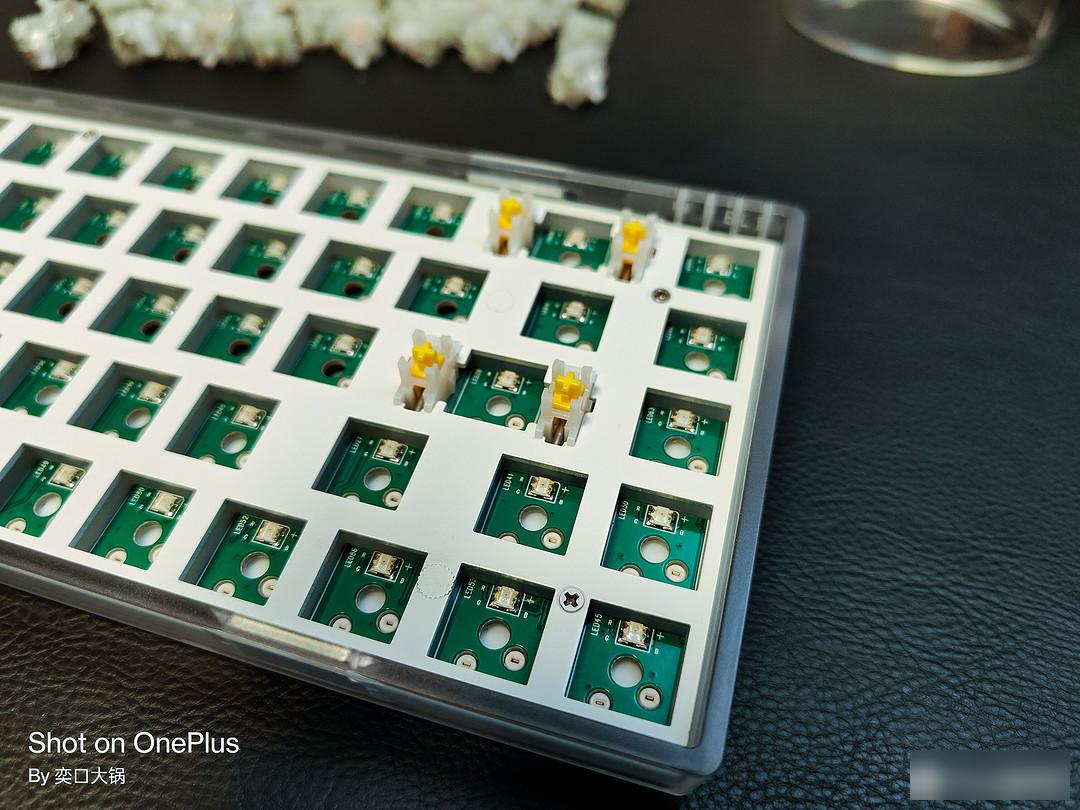

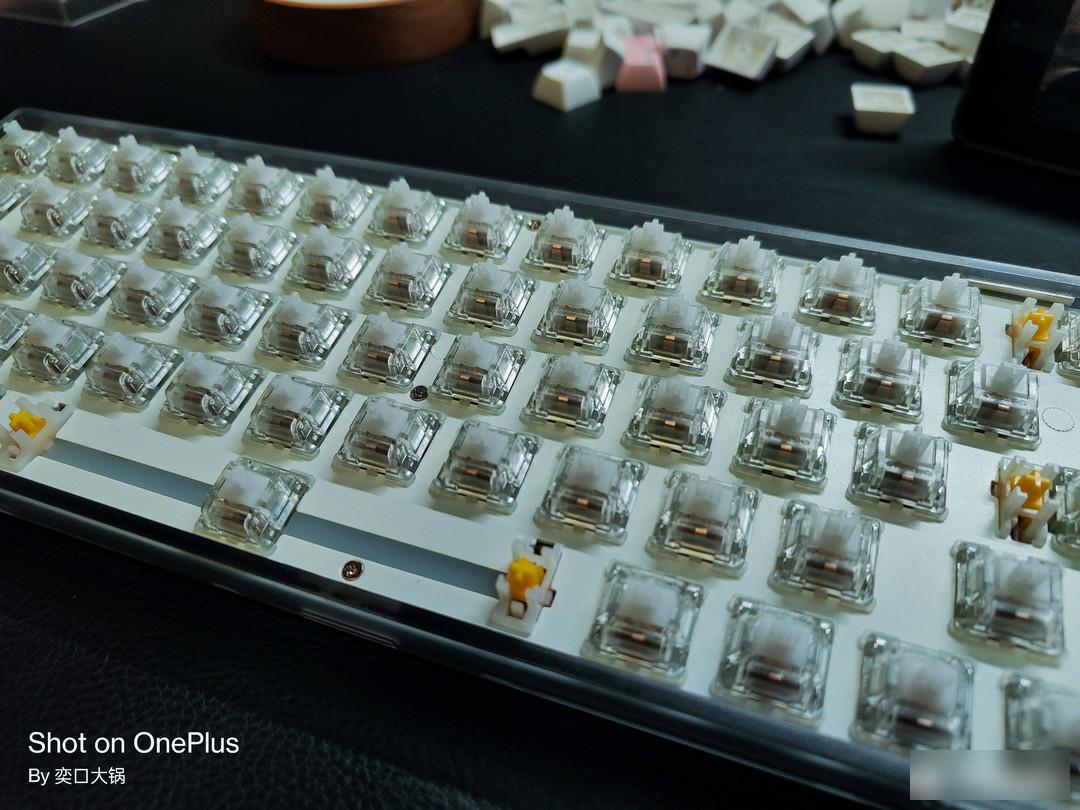

The shaft body is divided into five-legged shaft body and tripod shaft body. The protrusion in the middle of the bottom of the shaft seat and the two metal sheets are tripods, and the five-legged body is based on the tripod with two plastic positioning feet. How to confirm whether you need to buy a tripod or a pentapod? You must first confirm the support of the kit. The five-legged kit can be compatible with the tripod shaft, but not vice versa. So if you want to save trouble, you can just buy the tripod shaft directly. Otherwise, you will have to "pedicure" the shaft body like the author.

All kinds of shafts are mechanical switches, which need to be installed on the circuit connected to the keyboard on the PCB before they can be used. For manufacturers, finished keyboards, products with only one plate to be welded, are the most suitable for assembly line and automation. It is much easier to get a hot-swappable kit and install it by yourself. It is much easier to weld the shafts one by one.

keycap

Except for some keys of individual keyboards that require special-sized keycaps, most of the others just press the keycaps directly on the shaft body. The price of keycaps ranges from low to high, and to be honest, the water is really deep. A considerable part of the keycaps rely on marketing to support the high price, and the actual workmanship and quality cannot afford the high price. If you buy keycaps by yourself, you can try the explosive models first.

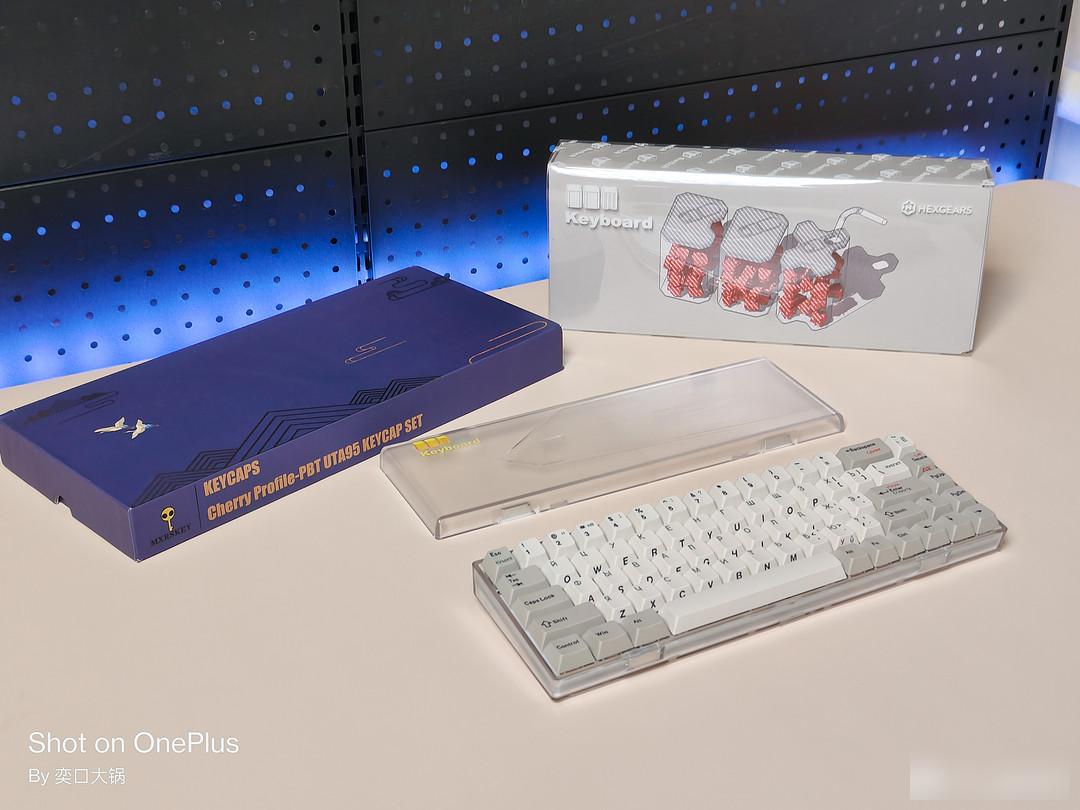

The matching keycaps this time are UTA-95 Russian original retro keycaps of MXRSKEY Mars Key. The full set of 141 keys adopts double-sided dye-sublimation printing technology on the front and side. It is the first keycap on the market with a wall thickness of 1.7mm.

Keycaps are mainly made of ABS, PBT, POM, and PC. Among them, ABS is softer and feels relatively soft, so it is easier to oil; PBT is harder than ABS, and even relying on process treatment can solve the problem. Problem, but you can still feel a little matte; the material of POM is black, so the third-party factories will basically not use it, and only the original original keyboards from manufacturers such as Cherry will be used.

The basic cost of raw materials is here, and the cost of mold opening must also be calculated. The higher the precision of the mold, the higher the cost of mold opening. The price span of the keycaps is very large, but the overall quality difference can indeed be seen. Taking the two sets of keycaps in hand, it is obvious that the gap in the level of craftsmanship can be seen. Regardless of the internal flatness or the consistency of the keycap wall thickness, the keycap of Mars Key UTA95 retro Russian is better.

When selecting keycaps, you should also pay attention to the height. The height of the original factory, OEM height, SA and XDA heights are relatively large. SA is the highest keycap, and sometimes it will be tiring to use. The height of OEM and original factory appears most on the finished keyboard. The height of XDA basically has no height difference. .

In addition to the feel, the cavity size and internal neatness of the keycap will also affect the timbre of the keyboard cavity sound. The "mahjong sound" pursued by many people is to reduce vibration and reduce the sound in the keyboard shell through sound-absorbing cotton or Gasket structure. Moreover, keycaps with insufficient internal processing often represent a gap in the overall process, and the uniformity of the material will be poorer, which will lead to differences in natural sound performance.

The printing process of the keycap characters is also a point of concern to everyone. Earlier, due to technical limitations, it was basically monochrome. From the initial laser engraving, silk screen printing and two-color molding/two-color injection molding to dye sublimation and coating inkjet, and now multi-color dye sublimation, the printing effect of keycaps is now much stronger than before.

The problem of three-leg/five-leg compatibility has been mentioned before, anyway, my Soda68 has 68 keys, so I need to trim 136 legs, which really hurts my hands. If the keyboard is self-assembled, it is recommended to choose a tripod shaft body, which can avoid a lot of trouble.

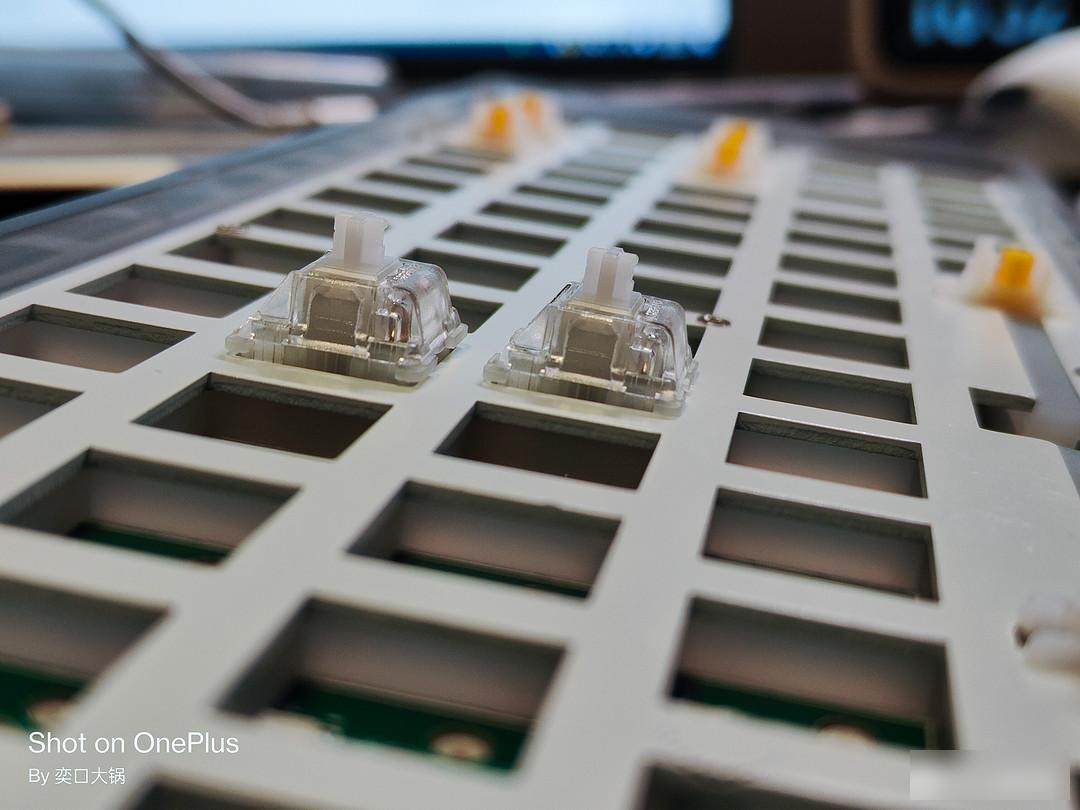

After the shaft body is corrected, it can be installed. If the trimming is uneven, the shaft body cannot be installed flush. Taking the installation of these two shafts as an example, the shaft on the left is not completely attached to the positioning plate, and must be re-trimmed. At the same time, you need to pay attention to the position of the metal pin, and remember to align the position to prevent breaking the shaft.

The same 68-column keyboard will also have different key definitions, mainly because the rightmost column is not necessarily the same. It is much faster to install according to the official manual than to try the keys back and forth.

The installation of the tripod shaft is also prone to problems. If the alignment is not accurate, it is easy to bend the two metal pins. Therefore, after the shaft body is installed, it is necessary to perform a key test. The keys that cannot be recognized after pressing are basically the pins that are not installed in place. Just pull it out and re-install it.

In our opinion, the keyboard is just a tool, and there is no need to add too much added value. If you are not very rich and free, there is no need for a limited collection, and if you are a personal hobby, you don't want to comment much. Compared with the big keyboard market, customization is only a small segment. It is the author's consistent guiding ideology to be able to obtain the required equipment at a cheaper price. Just pick the most suitable hardware within your affordability.

Factory Adress: No.11,FengpingRoad