TTC high-speed rail Venus axis and Neptune axis evaluation: smoother and smoother

TTC held the 2023 new product launch conference on the 23rd of this month, and officially released a brand new high-speed rail-style long track structure series shaft. On the basis of the traditional MX shaft, this series of shafts further optimizes the pressing stability and light transmission performance, and also greatly improves the smoothness of the hand feeling. Let's take a look with the author next.

The shafts of the high-speed rail long track structure series provide two types of shafts, which are named Venus shaft and Neptune shaft respectively. It is very convenient to distinguish them by different shaft cover colors. The shaft packaging continues TTC’s gift box packaging. The black plastic bottom case with a transparent upper cover is beautiful and generous. The anti-drop and pressure-resistant box can also protect the shaft well. It can also be used to put some other items, which is very practical.

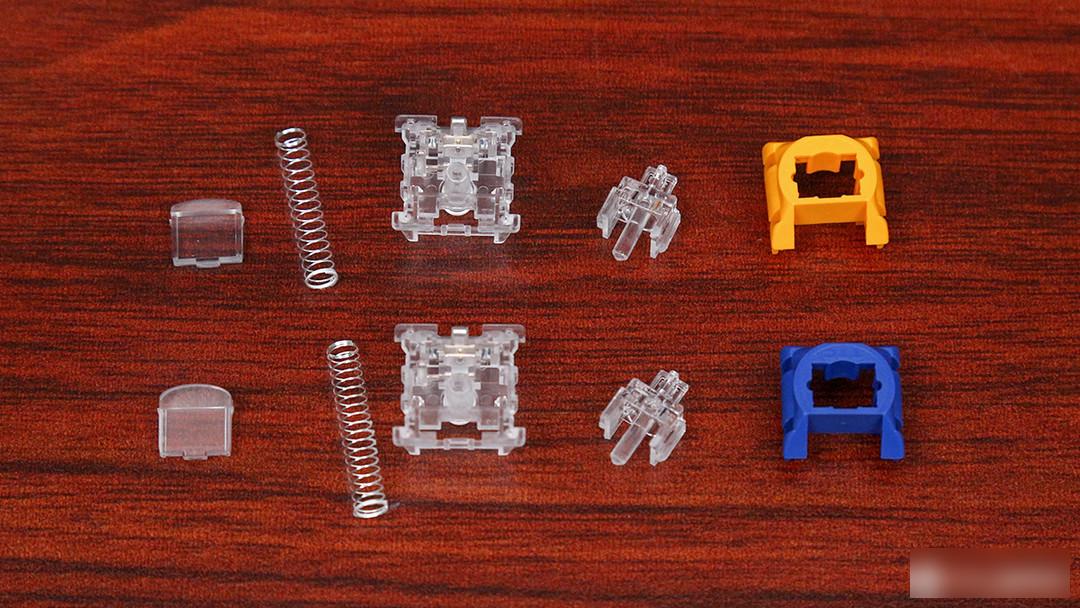

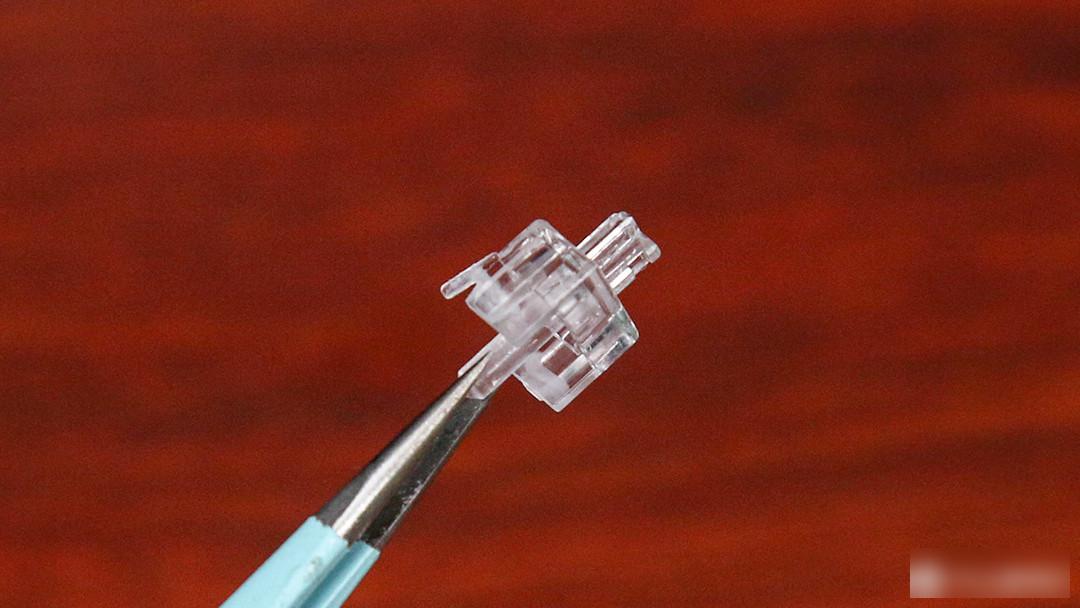

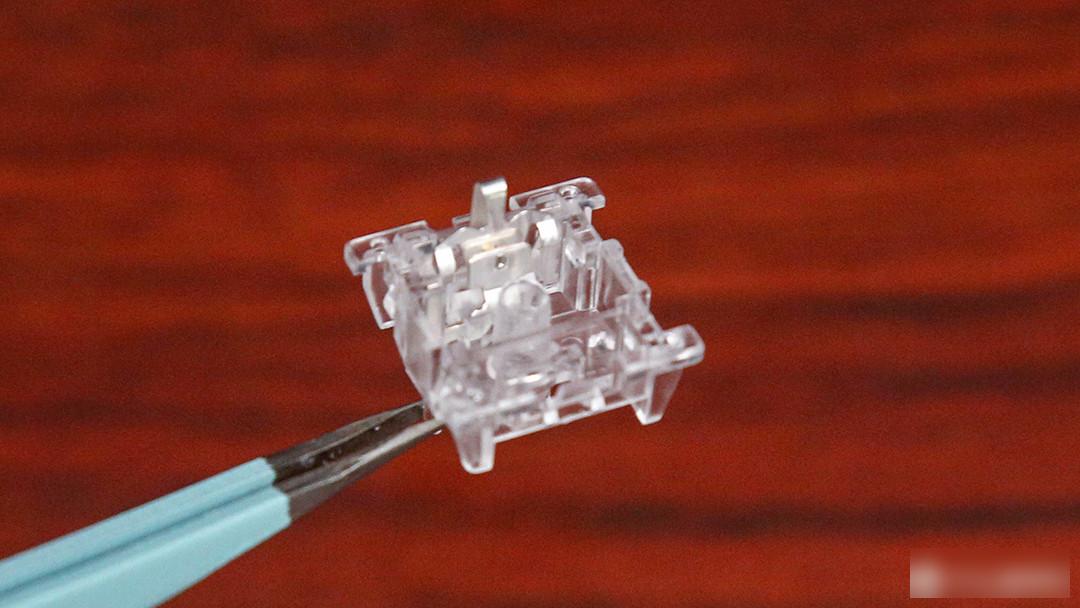

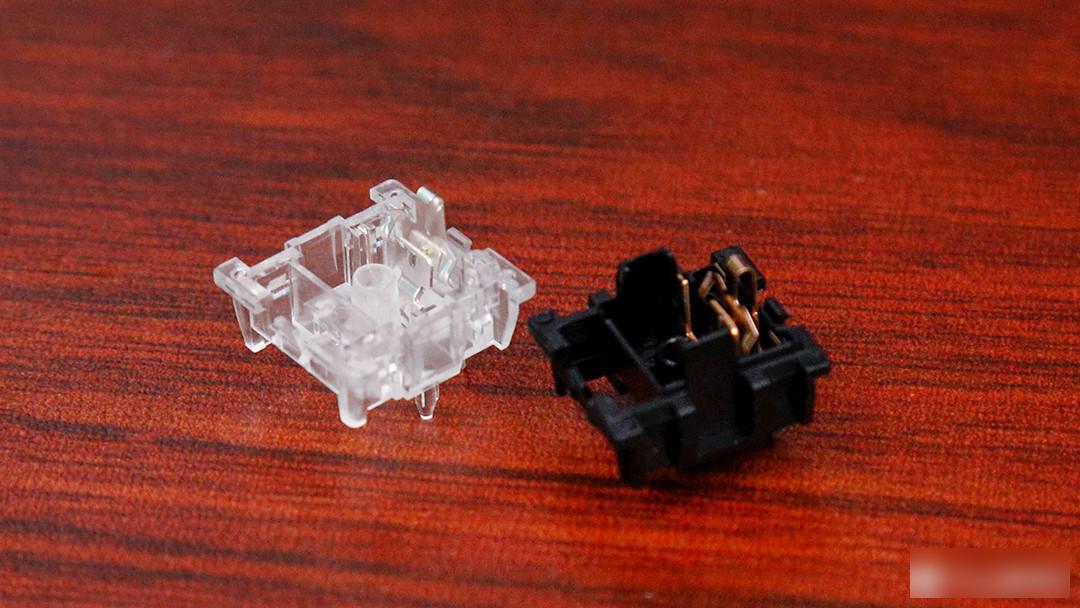

The TTC high-speed rail Venus shaft and Neptune shaft are based on the traditional MX, and the shaft cover, shaft seat, and shaft center have been upgraded in detail. The two shafts use shaft covers of different colors to distinguish the type of shaft body. The shaft cover adopts a double-layer design style, with a round top and a square design at the bottom. With the square shaft seat scheme, it is more in line with the "round sky and place" "philosophical thought. The shaft cover adopts two different processes of smooth surface and frosted surface. With the double-layer design and transparent shaft seat and shaft center, the visual layering is richer and the overall viewing experience of the shaft body is improved. The two shafts are equipped with an independent light guide column structure as standard, and with the transparent shaft seat and shaft center, it can also bring better light transmission performance. The shaft seat part adopts a five-leg scheme, which can improve the stability after installation and bring better knock feedback feel.

The TTC high-speed rail Venus shaft and Neptune shaft adopt the four-corner buckle shaft cover scheme, which is tightly fixed with the shaft seat, stable and strong, and also has a better dust-proof effect, preventing dust impurities from entering the shaft body and affecting the use feel. and service life. The independent light guide column structure combined with the transparent shaft seat and shaft center can make the shaft body have double light-transmitting channels, further improving the lighting performance of the keyboard. The single-stage spring can bring more linear and stable pressing feedback, and cooperate with TTC's silver plating process to improve the oxidation resistance and durability of the internal metal parts, and also increase the service life, making it more reliable and durable. The sliders on both sides of the transparent shaft are extended to 6.0mm, and with the long guide rail on the shaft cover, the swing is small and the connection is tight, which further improves the stability when pressing and ensures a smooth and smooth hand feeling. Different from the traditional MX structure shaft body, the TTC high-speed rail shaft body adopts an innovative long track integrated shaft cover, which allows the shaft center slider to slide in the track all the time, effectively reducing the shaft shaking problem. TTC adopts high-precision molds, so that the shaft cover and the shaft center are tightly connected, and at the same time, there will be no problems of sticking and blocking, making the knocking feel smoother and more stable, which is almost comparable to the double-sided wall shaft.

Both the TTC high-speed rail Venus switch and Neptune switch adopt a linear feel scheme. The trigger pressure of the Venus switch is 45gf, the trigger stroke is 1.8mm, and the total stroke is 3.8mm; the trigger pressure of the Neptune switch is 41gf, the trigger stroke is 2.0mm, and the total stroke is 3.8mm. billion times. Both shafts are linear shafts with light pressure. The internal springs, guide rails and other positions have also been factory-lubricated. The pressing performance is light and smooth, and the bottoming is soft and rebounds quickly. The pressing process is very stable and smooth, and there is no knocking noise. The control is proper, and the tactile feedback is still very good.

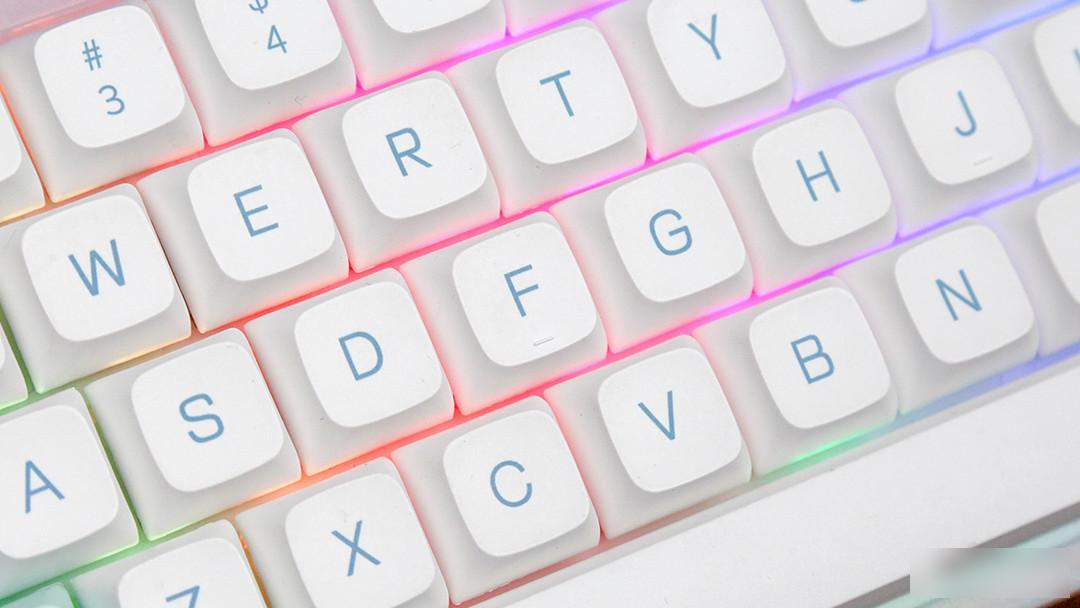

The double light transmission channel design also makes these two shafts have better light transmission performance. The independent light guide column and the position of the axis can refract and export the keyboard light, improve the light divergence, and spread the effect. The light effect has a good performance. It makes the keyboard light look soft and comfortable, and the color performance is more realistic and gorgeous. It can better display the RGB lighting effect of the keyboard and improve the overall visual perception of the keyboard. With the current popular transparent keycaps, it can also bring more brilliant lighting effects. .

Summarize:

The TTC high-speed rail-type Venus axis and Neptune axis adopt innovative structural solutions. The one-piece long track axis cover and the sliders on both sides of the extended axis core have a delicate structure, and the handle is firm and tight, which can bring users smooth and stable pressing performance. The dual light-transmitting channel solution can also improve the keyboard lighting rendering performance, bring users a better lighting experience, and bring users double satisfaction in terms of feel and look. These two switches will be first installed on Kezhi Z98 three-mode wireless mechanical keyboard, mechanical GK80 three-mode Gasket mechanical keyboard, and Fuling GP75 series keyboards. Interested users may wish to pay attention.

The author declares that there is interest in this article, please respect the author and the content shared, communicate friendly, and make rational decisions~

Factory Adress: No.11,FengpingRoad