Understand mechanical keyboard keycaps in one article

Hello everyone, I am Chen Shuaishuai, an anti-consumerist who understands digital.

Today, let’s talk to you about something that affects the feel of a mechanical keyboard—keycaps.

Next, I will talk to you about the common types of keycaps in the market from the aspects of keycap material, character processing technology, keycap height, and character engraving methods.

Keycap materials are mainly divided into the following types. Different materials feel different to the touch. The main differences between each material are as follows:

This is the most common keycap material in mechanical keyboards. The full name of this material is styrene plastic, which is engineering thermoplastics.

This material is used by many manufacturers because of its low melting point and relatively low cost of production, processing and color matching. ABS keycaps have better light transmission, so they are more suitable for use with mechanical keyboards with RGB lights.

But the biggest problem with this kind of keycap is its low durability and easy oiling. After a long time of use, the matte layer on the surface of the keycap will disappear, and the entire keycap will become shiny, and the sense and touch will be greatly reduced.

Some high-end ABS keycaps will spray a layer of wear-resistant material to reduce the probability of oiling, but this cost is relatively high, and generally only appears on higher-priced mechanical keyboard products. (Blow on Filco, the leader in ABS)

The PBT material is a polyester keycap with high hardness and crisp and delicate touch. After a long time of use, the fonts are not prone to wear and grease.

However, this kind of keycap has a higher melting point, is more difficult to process, and is also more difficult to color. The color vividness of the keycap will be much lower than that of ABS.

POM keycaps are thermoplastic crystalline polymers. This kind of keycap has the advantages of no oil, high density, and smooth and smooth feel. However, the color matching of this kind of keycap is relatively simple, and the processing is more difficult, and the production cost is higher. Few manufacturers use keycaps of this material.

The three keycap materials mentioned above can basically be installed on an entire keyboard for typing, while resin, metal, wood, rubber and other material keycaps are relatively small. The production cost of such niche keycaps is quite high, so it is recommended that you only choose a few as personalized keycap decorations.

Take resin keycaps as an example. Dozens of finished product experiments are required to make a satisfactory work. During this period, a lot of time and energy are spent. Moreover, the silicone molds used to make resin keycaps also have a service life. The time and energy are much higher than the keycaps of the previous three materials.

Because of their high price, resin and metal keycaps are mostly sold as a single piece, used for decoration and collection of key keys such as ESC space.

If you want to buy this kind of keycap, you can go to a second-hand platform like Mouyu to have a look.

After talking about the basis (material) of the keycap, let's take a look at the character craftsmanship of the keycap.

Laser engraving technology adopts laser engraving process, which has low manufacturing cost and is used in many entry-level mechanical keyboards. The keycap surface is uneven and not wear-resistant, which is its problem.

This is a process of processing characters and keycaps together. According to different processing procedures, it is divided into two-color injection molding and two-color molding.

Two-color injection molding is to make two colors together under one mold. The cost of this process is lower, and it is also called false two-color.

Two-color molding is more advanced. This process requires two sets of molds (first make the base color, and then add the second plastic material to another mold). Basically, the characters will not be worn off. Problems, but the more complex manufacturing process also brings higher costs. (If there is a keycap made of transparent material, it can make the letters transparent, which is very suitable for RGB backlit keyboards)

Dye-sublimation uses high temperature to sublimate solid resin ink into a gaseous form, and then penetrates this ink into the surface of the keycap.

It should be noted that only high temperature resistant PBT material keycaps can be sublimated. The advantage of this process is that it can make the characters more shiny and not easy to wear. The disadvantage is that it has poor light transmission and is not suitable for RGB keyboards.

In terms of durability, the keycap character processing technology is sorted as follows: Two-color forming>sublimation>laser engraving

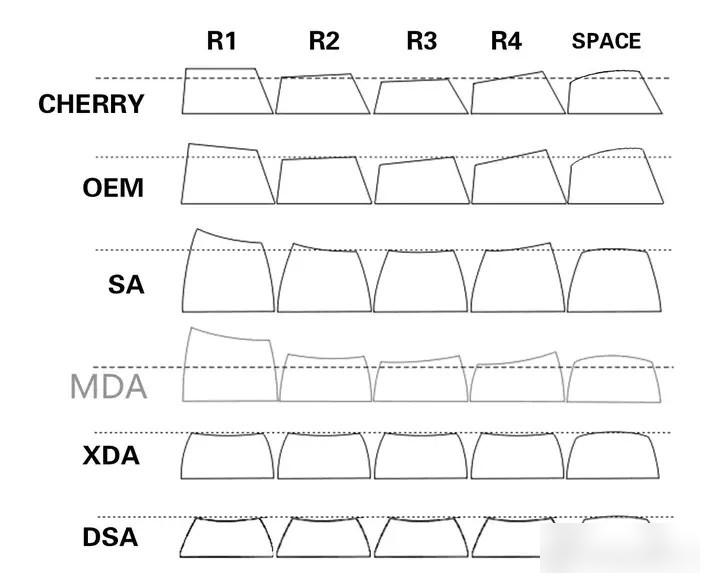

The height of the keycap is another important factor that affects the feel and sound of the keyboard. A keycap suitable for your height can make you more comfortable when using it, and also allow you to better enjoy the tapping feedback brought by the shaft.

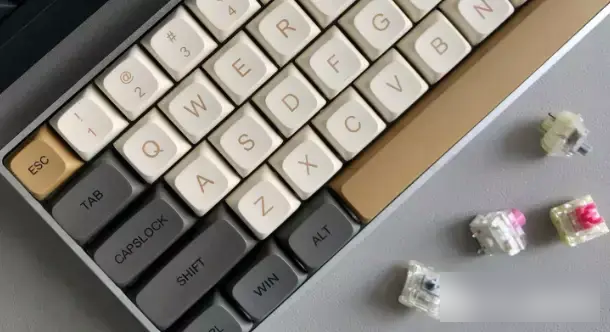

The original factory refers to the cherry, which is a very common keycap height on the market. Most people will feel more comfortable using keycaps of this height. Less prone to accidental touch, more suitable for touch typing.

This height is similar to the original keycap, but it will be higher overall, and it is also a type of height used more in mass-produced keyboards. Because the height will be higher, the cavity will be larger and the sound will be louder when typing.

Viewed from the side, this kind of keycap will present a curved stepped shape with a low center and high sides. The four sides of a single keycap are rounded, so it is called a ball-like height.

There is a kind of keycap with uniform height and no gradient.

The original creator is Wen Ruo, a domestic designer, but because of its ease of use, it was popularized by many unauthorized people. This type of keycap has a larger finger contact surface, so typing is more comfortable. It can better restore the feel of the shaft body, and it is very good to use it with the paragraph shaft. However, XDA height keycaps also have the disadvantage of being easy to accidentally touch, and are not recommended for compact keyboards.

It is higher than XDA, and the height of each row of keycaps is uniform. After the height is increased, the sound effect of the wooden fish sound will be more obvious when you hit the keyboard. Although the tactile feeling has dropped a bit, the sense of hearing will improve a lot.

Finally, add a little keycap character engraving method

At present, the most mainstream character engraving method is to engrave all the words and characters on the top of the keycap.

"Side engraving" is also called "front engraving". All words and characters are engraved on the side of the keycap. The advantage of such engraving is that the characters on the keycap will not be worn out due to long-term contact with fingers. (There will still be oil on the surface in contact with your fingers)

Anti-human keycaps, there is no mark on all keycaps. Experts in blind typing can consider it, but ordinary people don't recommend it. .

For more information about keyboard purchase and keyboard knowledge, welcome to my homepage to view.

Factory Adress: No.11,FengpingRoad