VERTEX (Vita Kesi) V1 axis prospect丨Assiduous study, final refinement

A New Axis Worth Watching

VERTEX - V1

Assiduous study, final refinement

Although there were early rumors that VERTEX would set foot in the shaft field, as time went by, this matter was slowly left in the deep sea of memory. But VERTEX never gave up on this project.

On March 26th, VERTEX released an "IC" on the front line of the equipment, introducing their upcoming custom shaft - VERTEX V1

Their vision is to create a product that follows the classic MX switch type, continuously improve the performance of the switch body through mold customization, and at the same time give back to the majority of keyboard players at a reasonable price, taking this as an opportunity to establish a long-term operation and sales system.

The words "follow the classics" are quite memorable, but let's take a look at the specific parameters before discussing them.

Materials and parameters

In terms of materials, first of all, the classic nylon material and POM shaft are matched with the classic cherry shaft.

There are different opinions on the forum about the choice of material for the cherry shaft shell. I personally think that early keyboards were mostly welded, so Cherry chose nylon reinforcement to improve the high temperature resistance of the shell. However, with the advancement of technology and the emergence of hot-swappable shaft seats, the restrictions on the material of the shaft shell have been greatly reduced, and we also have more choices and possibilities.

Look at the parameters

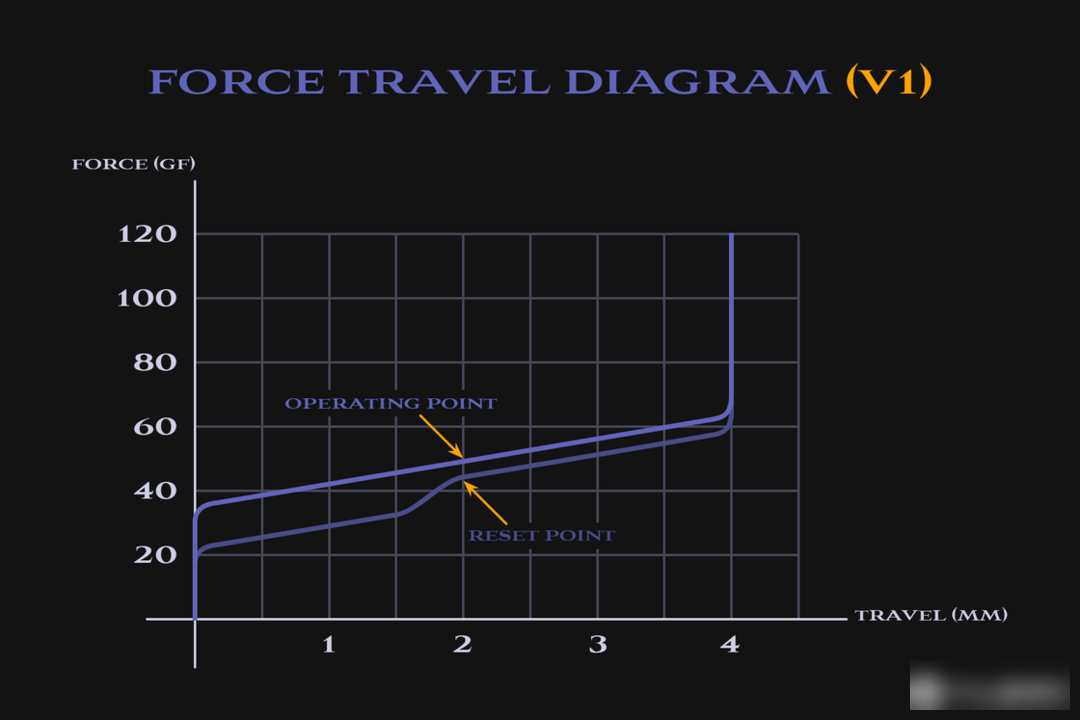

Full stroke: 4.0±0.3mm

Pre-stroke: 2.0±0.3mm

Initial strength: 35gf(min)

Operating force: 50±10gf

Bottom force: 62±10gf

Spring: 15mm stainless steel non-gold-plated spring

Although the data of VERTEX is exactly the same as that of Cherry red shaft, the design of using spherical point-shaped shaft core column to touch the bottom is completely different from Cherry's style.

Now there are a lot of introductions and typing sound tests for this switch on the platform. Maybe VERTEX initially envisioned making a modern version of the Cherry red switch, but judging from the final product, it seems that it has nothing to do with hg.

Back on the topic of cherry flavor, this is an interesting question because everyone may have a different opinion. I had a chat with my cousin about this when the shaft came out, and he had an interesting answer.

The taste of Cherry I know is also because of the special nylon material of Cherry. All switch factories imitated and borrowed from Cherry in the early days, but they just couldn't solve the problem of nylon material. And now many players talk about the rustling sound. I have never thought this is a characteristic of Cherry, and I even think it is a disadvantage. I believe that all players who played Cherry in the past will not like its rustling sound, which is why they will do it. main reason for lubrication

I personally think that the unique charm of the Cherry shaft may lie in its sandy feeling after lubrication. This strange hand experience is precisely the important source of the Cherry flavor. Just like stinky tofu, it is because of its smell that people feel fragrant.

According to this IC post, summarize the following points:

JWICK used a brand new injection molding machine when producing the V1 shaft body

Gold-palladium alloy contacts are used, and optimized adjustments are made to weaken the shaking and shrapnel sound during impact.

As for the assembly line, point-spray fog surface treatment is added to obtain a better factory moist effect.

On the detection line, in addition to completing the basic detection, the screening of spring sound and shrapnel sound was also carried out.

JWICK is equipped with 3 injection molding machines and a new automatic operation line dedicated to the V1 axis to achieve rolling capacity support,

The launch of the V1 shaft this time has indeed brought many exciting elements, whether it is the product's publicity gimmick or consumers' expectations for its performance, it has reached a very high level. Especially considering its single price of 1.8 yuan, coupled with factory run and exclusive mold blessing, it is even more difficult to restrain curiosity about its performance. 1.8 JWK, with such cost performance, it is not difficult to make people look forward to the performance of this shaft.

Buying advice:

Since this axis is a long-term continuous supply type of large goods, you can wait for more players to buy and experience before making a choice. Of course, the reputation of VERTEX in the industry is obvious to all, buy early and experience early.

Factory Adress: No.11,FengpingRoad